When it comes to heat dissipation in electronic devices, vapor chambers play a vital role in keeping them cool. In this article, we will delve into the inner workings of vapor chambers and how they effectively transfer heat away from sensitive components.

What is a Vapor Chamber?

A vapor chamber is a key component in thermal management systems, consisting of a sealed metal container with a small amount of liquid inside. When heat is applied to the surface of the chamber, the liquid evaporates and spreads to other areas, effectively distributing the heat evenly.

Evaporative Cooling Process

As the liquid evaporates inside the vapor chamber, it absorbs a significant amount of heat from the surface. This phase change from liquid to vapor allows for efficient heat transfer, as the vapor travels to cooler regions where it condenses back into liquid form, releasing the absorbed heat in the process.

Heat Conduction in Vapor Chambers

Vapor chambers are highly efficient at conducting heat due to the rapid movement of vapor within the chamber. This continuous cycle of evaporation and condensation allows for quick heat dissipation, making them ideal for applications that require effective thermal management.

Benefits of Vapor Chambers

Compared to traditional heat spreaders, vapor chambers offer improved thermal conductivity and heat distribution. They are lightweight, cost-effective, and can be custom-designed to fit specific electronic devices, making them a popular choice for high-performance applications.

Applications of Vapor Chambers

Vapor chambers are commonly used in electronic devices such as smartphones, laptops, gaming consoles, and high-end computer systems. They help prevent overheating and ensure optimal performance by efficiently dissipating heat generated during operation.

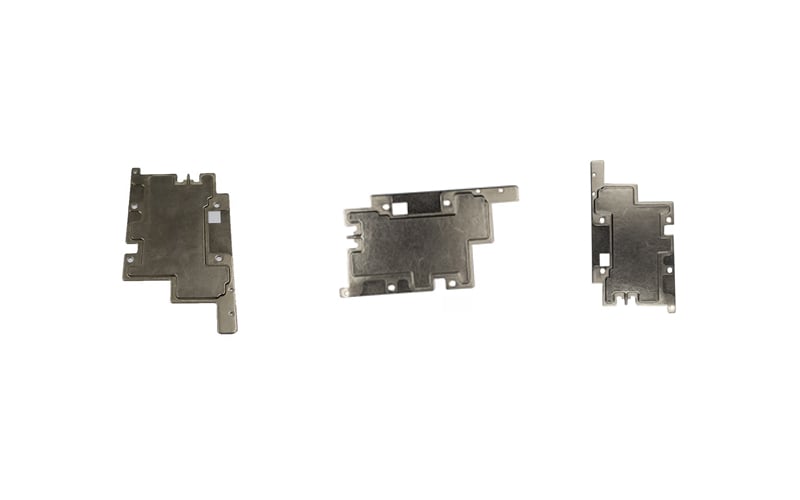

Manufacturing Process of Vapor Chambers

Vapor chambers are typically constructed using copper or aluminum materials that have excellent thermal conductivity. The manufacturing process involves sealing the chamber, filling it with a small amount of working fluid, and ensuring a tight seal to prevent any leaks during operation.

Thermal Interface Materials

To maximize the heat transfer efficiency of vapor chambers, thermal interface materials such as thermal paste or pads are often used to improve contact between the chamber and the heat source. This helps reduce thermal resistance and ensures efficient heat dissipation.

Integration with Heat Sinks

In some applications, vapor chambers are integrated with heat sinks to further enhance heat dissipation capabilities. The combination of these two thermal management components helps maintain low operating temperatures and prolong the lifespan of electronic devices.

Future Innovations in Vapor Chamber Technology

Ongoing research and development in vapor chamber technology aim to improve thermal performance, reduce manufacturing costs, and make them more environmentally friendly. Advances in materials and design are driving innovation in thermal management solutions for next-generation electronic devices.

Conclusion

Understanding how vapor chambers work is essential for designing efficient cooling solutions for electronic devices. With their superior heat transfer capabilities and versatility, vapor chambers continue to play a crucial role in maintaining optimal performance and reliability in a wide range of applications.