What Are power resistor heat sinks?

Power resistor heat sinks are an essential component in many electrical systems, particularly those that generate a large amount of heat and dissipate it through resistors. In simple terms, a resistor is an electrical component that resists the flow of current, which in turn generates heat. In high-power applications, this heat can quickly build up and cause damage to the system which is where heat sinks come in handy.

How Do Power Resistor Heat Sinks Work?

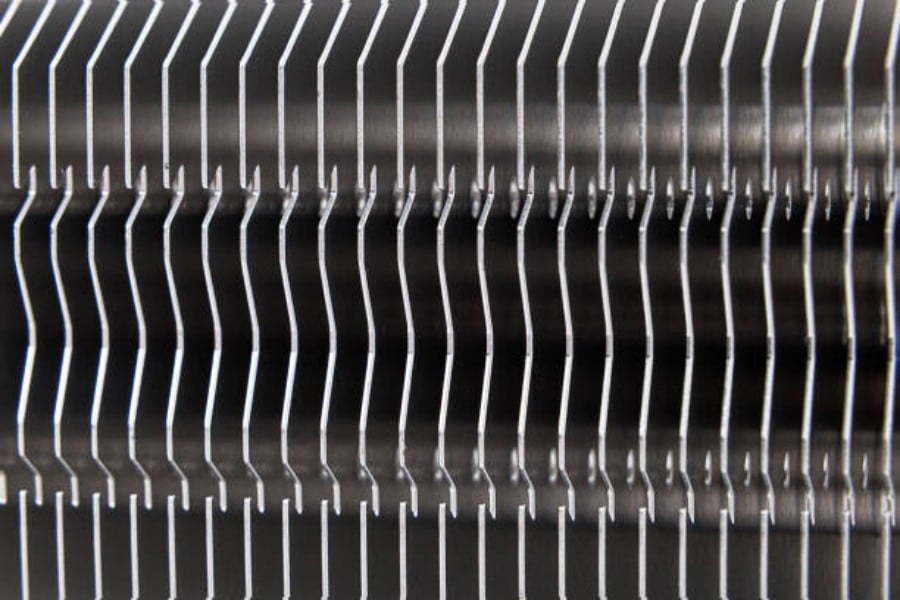

Power resistor heat sinks are designed to absorb and dissipate heat away from the resistor, keeping the temperature of the resistor at a safe operating level. A heat sink works by providing a large surface area over which heat can be dissipated, typically through the use of fins, exposed surfaces or active cooling mechanisms. The heat sink is then cooled by a flow of air or a fluid to keep the temperature down and prevent damage to the resistor or other components in the system.

Types of Power Resistor Heat Sinks

There are many different types of power resistor heat sinks available, ranging from simple passive cooling devices to more sophisticated active cooling systems. Some of the most common types of heat sinks include:

- Aluminum heat sinks

- Copper heat sinks

- Extruded heat sinks

- Bonded fin heat sinks

- Pin fin heat sinks

- Liquid-cooled heat sinks

Factors to Consider When Choosing a Power Resistor Heat Sink

When selecting a power resistor heat sink, there are several factors to consider to ensure that the heat sink is suitable for your specific application. These factors include:

- Power rating of the resistor

- Maximum operating temperature

- Available space for the heat sink

- Environmental considerations (e.g. exposure to dust, liquids or extreme temperatures)

- Overall cost and ease of installation

Benefits of Using a Power Resistor Heat Sink

There are many benefits of using a power resistor heat sink in your electrical system, including:

- Reduction in heat-related damage to your components

- Improved efficiency and reliability of the system

- Extended lifespan of the components due to reduced heat buildup

- Potentially lower overall system costs due to fewer replacements and repairs

Installation and Maintenance of Power Resistor Heat Sinks

Proper installation and maintenance of power resistor heat sinks is critical to ensure optimal performance of the system and avoid damage or failure. When installing a heat sink, be sure to follow the manufacturer's instructions carefully, and make sure that the heat sink is securely attached to the resistor, and any associated cooling mechanisms are properly installed and tested. Regular maintenance of the heat sink, including cleaning and inspection, is also recommended to ensure that the heat sink is functioning correctly and any potential issues are addressed before they result in costly damage to the system.

Applications of Power Resistor Heat Sinks

Power resistor heat sinks are used in a wide range of electrical systems, including:

- Motor drives

- Power electronics

- Automotive components

- Aerospace industry

- Solar power systems

- Telecommunications equipment

Final Thoughts

Power resistor heat sinks are an essential component in many electrical systems where high-power applications can generate excessive heat that needs to be dissipated to prevent damage to the system. By selecting the right heat sink for your application and following proper installation and maintenance procedures, you can ensure that your system operates efficiently and reliably for many years to come.