The Importance of Heat Dissipation in Various Industries

Heat dissipation is a critical process in many industries where heat-generating components are used. Efficient cooling is essential to prevent overheating, which can lead to reduced performance, premature failure, or even safety hazards. Heat dissipation materials play a crucial role in managing and directing heat away from these components. In this article, we will explore the Types and Characteristics of Heat Dissipation Materials commonly used in various applications.

1. Thermal Conductive Pads: Enhancing Heat Transfer

Thermal conductive pads are widely used in electronic devices, such as computers, smartphones, and automotive electronics, to enhance heat transfer. These pads are made from materials with high thermal conductivity, allowing them to efficiently conduct heat away from the heat-generating components. Silicone-based thermal pads are commonly used due to their excellent thermal conductivity and electrical insulation properties.

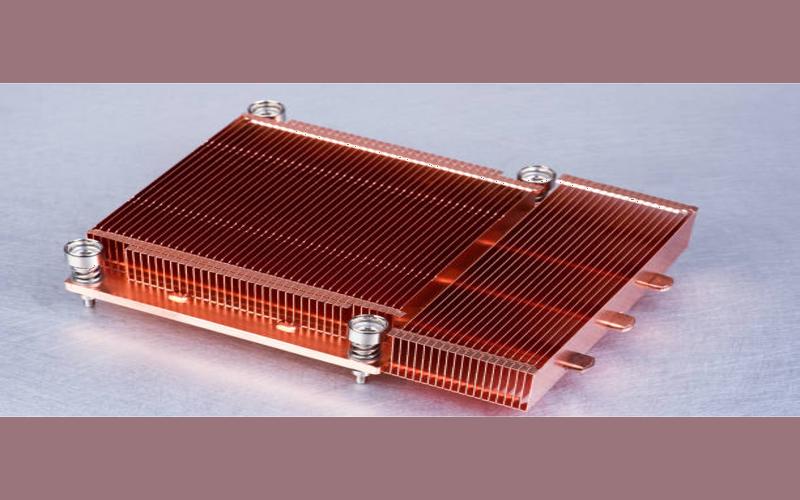

2. Heat Sinks: Maximizing Surface Area

Heat sinks are passive cooling devices that maximize the surface area available for heat dissipation. They are often made from aluminum or copper, which have high thermal conductivity. The intricate fin structures of heat sinks increase the effective surface area, facilitating the transfer of heat to the surrounding air. Heat sinks are commonly used in CPUs, GPUs, power amplifiers, and other high-power electronic components.

3. Heat Pipes: Efficient Heat Transfer over Longer Distances

Heat pipes are highly efficient heat transfer devices that can transport heat over longer distances. They consist of a sealed copper or aluminum tube filled with a working fluid, typically water or a refrigerant. Heat pipes rely on the phase change of the working fluid to transfer heat from the heat source to the heat sink. They are commonly used in applications where traditional cooling methods are not feasible, such as in laptops, satellites, and LED lighting.

4. Thermal Greases: Bridging Air Gaps

Thermal greases, also known as thermal compounds or thermal interface materials (TIMs), are used to fill the microscopic air gaps between heat-generating components and heat sinks. These greases have high thermal conductivity and low thermal resistance, enabling efficient heat transfer between the two surfaces. Silicone-based thermal greases are commonly used due to their stability, ease of application, and compatibility with a wide range of materials.

5. Phase Change Materials (PCMs): High Heat Absorption Capacity

Phase change materials (PCMs) are substances that can store and release large amounts of heat during the phase transition process. PCMs can absorb heat when they change from solid to liquid and release heat when they solidify again. This property makes them ideal for applications where transient or intermittent heat loads are present. PCMs are used in various industries, including electronics, construction, and energy storage.

6. Liquid Cooling Systems: Efficient Heat Removal

Liquid cooling systems are becoming increasingly popular for high-performance electronic devices and data centers. These systems use a liquid, such as water or specialized coolants, to remove heat from the components. The liquid absorbs the heat and transfers it to a radiator, where it is dissipated into the surrounding environment. Liquid cooling systems offer superior cooling performance compared to traditional air cooling methods, enabling higher overclocking capabilities and prolonged component lifespan.

7. Graphene-Based Materials: Excellent Thermal Conductivity

Graphene, a two-dimensional carbon material, has exceptional thermal conductivity properties, making it a promising material for heat dissipation applications. Graphene-based materials, such as graphene films or graphene composites, can effectively transfer heat away from heat-generating components. These materials are lightweight, flexible, and have a high surface area, making them suitable for various industries, including electronics, aerospace, and automotive.

8. Ceramic-Based Materials: High Thermal Stability

Ceramic-based materials, such as aluminum nitride (AlN) and boron nitride (BN), exhibit excellent thermal stability and low thermal expansion. These materials can withstand high temperatures and thermal shocks, making them suitable for harsh environments. Ceramic-based heat dissipation materials are commonly used in power electronics, LED lighting, and other high-temperature applications where reliability and longevity are crucial.

9. Carbon-Based Materials: Lightweight and Durable

Carbon-based materials, such as carbon nanotubes (CNTs) and carbon fibers, offer a unique combination of lightweight, high thermal conductivity, and mechanical strength. These materials can efficiently dissipate heat while adding minimal weight to the overall system. Carbon-based heat dissipation materials find applications in industries such as aerospace, automotive, and sports equipment.

10. Hybrid Heat Dissipation Solutions: Optimal Performance

Hybrid heat dissipation solutions combine multiple materials and technologies to achieve optimal cooling performance. For example, a hybrid solution may incorporate a heat pipe with a heat sink or integrate thermal greases with thermal pads. These solutions are tailored to specific applications, providing efficient heat transfer, enhanced reliability, and improved overall thermal management.