An Introduction to Stamped Heat Sinks

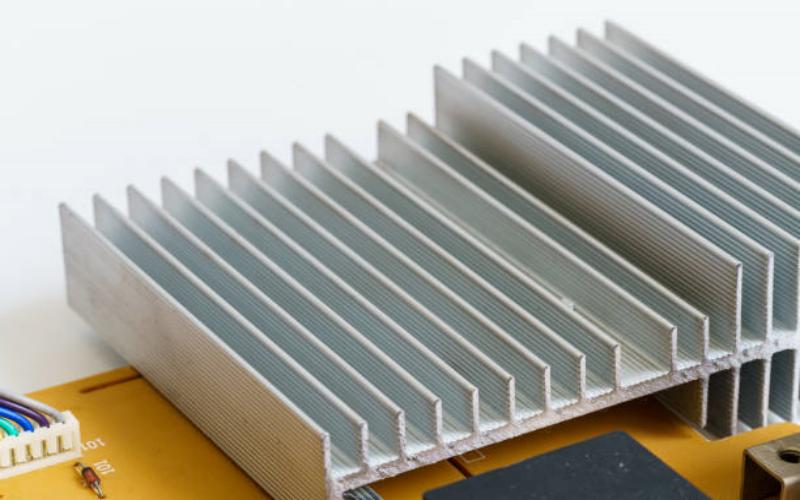

Heat sinks play a crucial role in the efficient cooling of electronic devices. One particular type, known as stamped heat sinks, has gained significant popularity in recent years. This article will explore the widespread use of stamped heat sinks and shed light on their numerous benefits and applications.

The Advantages of Stamped Heat Sinks

Stamped heat sinks offer several advantages over other types of heat sinks. Firstly, they are cost-effective to produce due to their manufacturing process. Stamping involves using a die to cut and shape the metal, resulting in reduced material waste and lower production costs. Additionally, this method allows for intricate designs and customization options.

Stamped heat sinks also have excellent thermal conductivity, which ensures efficient heat dissipation. The large surface area created by the stamping process allows for better heat transfer, making them ideal for high-power electronic components that generate significant heat.

Another advantage of stamped heat sinks is their lightweight nature. The stamping process enables the creation of thin fins without compromising structural integrity. This reduced weight is particularly beneficial in applications where weight is a concern, such as aerospace and automotive industries.

The Applications of Stamped Heat Sinks

Stamped heat sinks find widespread use in various industries due to their versatility and effectiveness. Here are some key applications:

1. Consumer Electronics

In consumer electronics, such as laptops, smartphones, and gaming consoles, stamped heat sinks are commonly used. These heat sinks efficiently dissipate the heat generated by the components, preventing overheating and ensuring optimal performance.

2. Automotive Industry

The automotive industry heavily relies on stamped heat sinks to cool critical components like power electronics, LED lighting systems, and electric vehicle motor controllers. These heat sinks help maintain the longevity and reliability of electronic systems in vehicles.

3. Renewable Energy

Renewable energy systems, like solar inverters and wind turbines, require effective thermal management to maximize energy conversion efficiency. Stamped heat sinks are often employed in these applications to dissipate excess heat and ensure consistent performance.

4. Industrial Machinery

Industrial machinery, including power supplies, motor drives, and control systems, generate substantial heat during operation. Stamped heat sinks provide an efficient cooling solution, promoting reliable operation and prolonging the lifespan of these machinery components.

5. Aerospace and Defense

The aerospace and defense sectors demand reliable and lightweight heat management solutions. Stamped heat sinks meet these requirements, ensuring the thermal stability of avionics systems, radar equipment, and military electronics.

The Future of Stamped Heat Sinks

As electronic devices continue to advance in complexity and power, the demand for efficient heat dissipation solutions will only grow. Stamped heat sinks are poised to play a significant role in meeting this demand. Ongoing advancements in stamping technology will further enhance their performance and versatility.

The use of innovative materials, such as aluminum alloys and copper, will also contribute to the evolution of stamped heat sinks. These materials offer excellent thermal conductivity and can be easily stamped into intricate shapes, enabling more effective heat transfer and customization options.

Conclusion

Stamped heat sinks have emerged as a popular choice in various industries due to their cost-effectiveness, thermal conductivity, and lightweight nature. From consumer electronics to aerospace applications, these heat sinks play a vital role in managing thermal issues and ensuring the reliable operation of electronic systems. With ongoing advancements in manufacturing techniques and materials, the future looks promising for stamped heat sinks.