Automotive stamped sink applications play a crucial role in the manufacturing process of vehicles. These sinks are used in a variety of automotive parts, from door panels to exhaust systems.

Benefits of Using Stamped Sinks in Automotive Manufacturing

One of the main advantages of using stamped sinks in automotive manufacturing is their cost-effectiveness. These sinks are incredibly versatile and can be used to create complex shapes with ease, making them an ideal choice for a wide range of automotive applications.

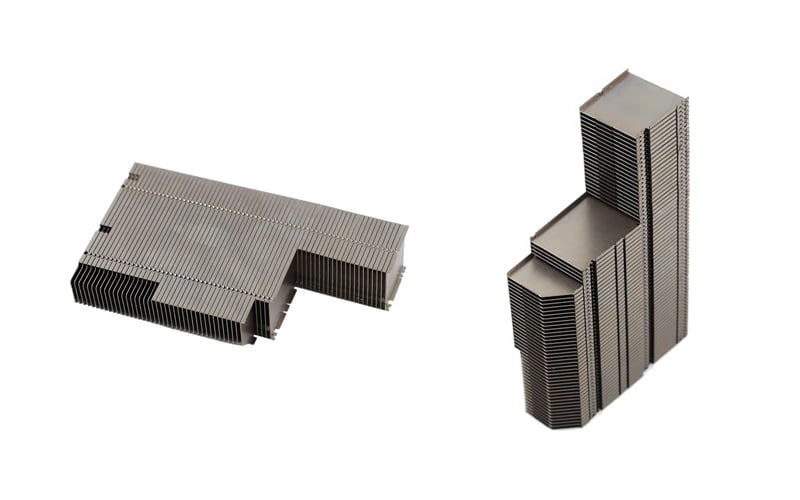

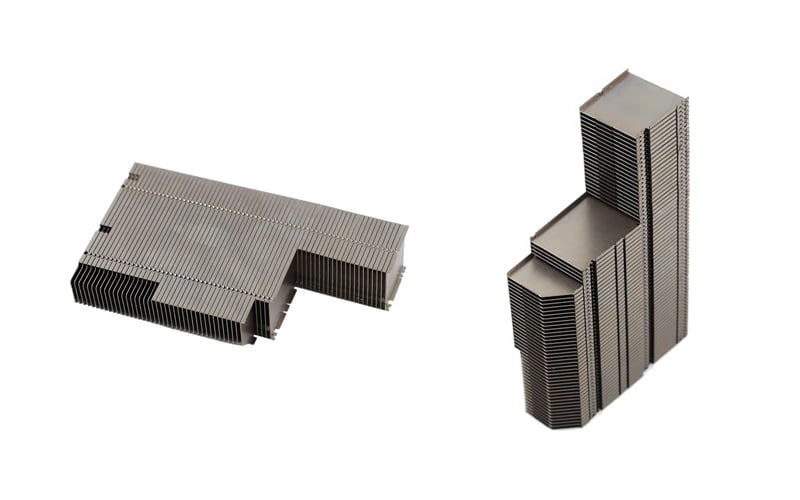

Types of Materials Used in Automotive Stamped Sink Applications

A diverse range of materials can be used in automotive stamped sink applications, including aluminum, steel, and copper. Each material offers unique advantages in terms of durability, weight, and resistance to corrosion.

Design Considerations for Automotive Stamped Sink Applications

When designing automotive stamped sink applications, engineers must take into account factors such as the intended use of the part, the material being used, and the manufacturing process. Careful consideration of these factors is essential to ensuring the quality and functionality of the final product.

Manufacturing Process for Automotive Stamped Sink Applications

The manufacturing process for automotive stamped sink applications involves several steps, including stamping, cutting, bending, and finishing. Each step must be executed with precision to ensure the final product meets the required specifications.

Applications of Automotive Stamped Sinks in Vehicle Components

Automotive stamped sinks are used in a wide range of vehicle components, including body panels, brackets, and heat shields. These sinks provide structural support and help to improve the overall performance and efficiency of the vehicle.

Advancements in Automotive Stamped Sink Technology

Advancements in technology have led to the development of innovative techniques for automotive stamped sink applications, such as laser cutting and 3D modeling. These advancements have enabled manufacturers to create more complex and precise parts for vehicles.

Importance of Quality Control in Automotive Stamped Sink Manufacturing

Quality control is essential in automotive stamped sink manufacturing to ensure the parts meet industry standards for safety and performance. Manufacturers must perform rigorous testing and inspection processes to identify and address any defects or issues in the production process.

Environmental Impact of Automotive Stamped Sink Applications

The use of automotive stamped sinks can have environmental implications due to the materials and energy consumed in the manufacturing process. Manufacturers are increasingly adopting sustainable practices to minimize the environmental impact of automotive stamped sink applications.

Future Trends in Automotive Stamped Sink Applications

As technology continues to advance, the future of automotive stamped sink applications looks promising. Manufacturers are exploring new materials, processes, and designs to enhance the performance, durability, and sustainability of these essential components in vehicle manufacturing.

Quote Inquiry

contact us