What are Variable Conductance Heat Pipes (VCHPs)?

Variable Conductance Heat Pipes (VCHPs) are advanced thermal management devices that use a combination of liquid and vapor phases to transfer heat. They have the ability to vary their conductance in response to changing thermal conditions, making them ideal for various aerospace, electronics, and industrial applications.

How do Variable Conductance Heat Pipes Work?

VCHPs operate based on a working fluid that evaporates in the warmer sections of the pipe and condenses in the cooler sections. The vapor phase moves towards the condenser section where it releases heat, and the liquid phase moves back towards the evaporator section to absorb more heat. This continuous cycle enables efficient heat transfer.

Advantages of Variable Conductance Heat Pipes

One of the major advantages of VCHPs is their ability to regulate heat transfer based on the operating conditions. They can adapt to varying heat loads, gravity orientations, and environmental factors, making them highly versatile. Additionally, VCHPs have high thermal conductivity and can operate over a wide temperature range.

Applications of Variable Conductance Heat Pipes

Variable Conductance Heat Pipes are commonly used in spacecraft thermal control systems, where they help dissipate excess heat generated by onboard electronics and equipment. They are also utilized in cryogenic systems, electronic cooling systems, thermal management of high-power LEDs, and more.

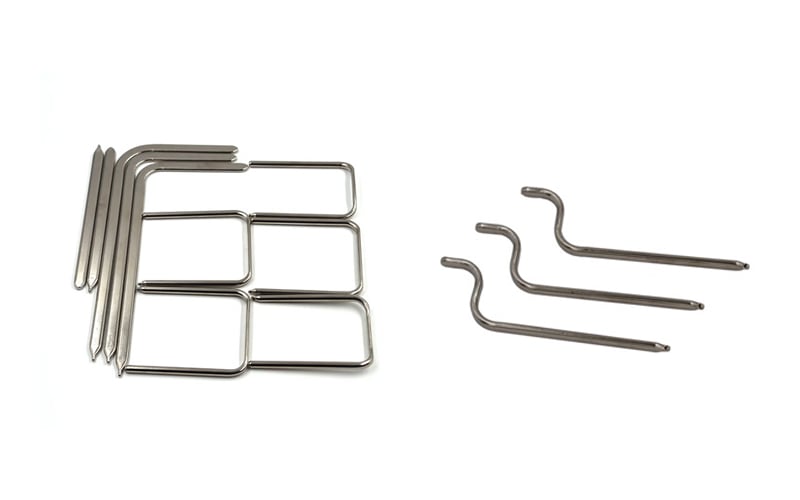

Design and Construction of Variable Conductance Heat Pipes

VCHPs consist of an evaporator section, adiabatic section, and condenser section, all connected by a sealed pipe containing the working fluid. The inner walls of the pipes are coated with a wick structure that assists in the capillary action and fluid circulation. The choice of working fluid and materials plays a crucial role in the performance of VCHPs.

Performance Characteristics of Variable Conductance Heat Pipes

The performance of VCHPs can be characterized by parameters such as thermal conductance, heat transfer limits, temperature range, operating orientation, and response time. Understanding these characteristics is essential for optimizing the efficiency and reliability of VCHPs in different applications.

Challenges in Implementing Variable Conductance Heat Pipes

Despite their numerous advantages, there are challenges associated with implementing VCHPs in certain environments. Factors such as fluid compatibility, working fluid containment, temperature limitations, and reliability under extreme conditions need to be carefully considered during the design and integration of VCHPs.

Future Developments in Variable Conductance Heat Pipes

Researchers are constantly exploring new materials, wick structures, and design configurations to enhance the performance of Variable Conductance Heat Pipes. The focus is on developing VCHPs with improved thermal conductance, reduced size and weight, and increased durability to meet the demanding requirements of modern thermal management systems.

Environmental Impacts of Variable Conductance Heat Pipes

The use of Variable Conductance Heat Pipes can contribute to energy efficiency and reduced environmental impact in various industries. By efficiently managing heat transfer and reducing the need for active cooling systems, VCHPs help lower energy consumption and carbon emissions, making them a sustainable choice for thermal management.

Conclusion

In conclusion, Variable Conductance Heat Pipes (VCHPs) are innovative thermal management devices that offer efficient and reliable heat transfer solutions for a wide range of applications. With their ability to adapt to changing thermal conditions, VCHPs are poised to play a crucial role in the advancement of aerospace, electronics, and industrial technologies.