Introduction

When it comes to heat sinks, there are two popular manufacturing processes to consider - extrusion and CNC machining. Each method has its own advantages and disadvantages, making it essential to understand the differences between the two. In this article, we will explore the key aspects of

extrusion vs. CNC heat sinks to help you make an informed decision for your cooling needs.

Extrusion Heat Sinks

Extrusion heat sinks are created by pushing a heated aluminum billet through a die to create the desired shape. This method is cost-effective for mass production and can produce complex designs with good thermal performance. However, the heat dissipation efficiency may not be as high as CNC heat sinks due to limitations in design flexibility.

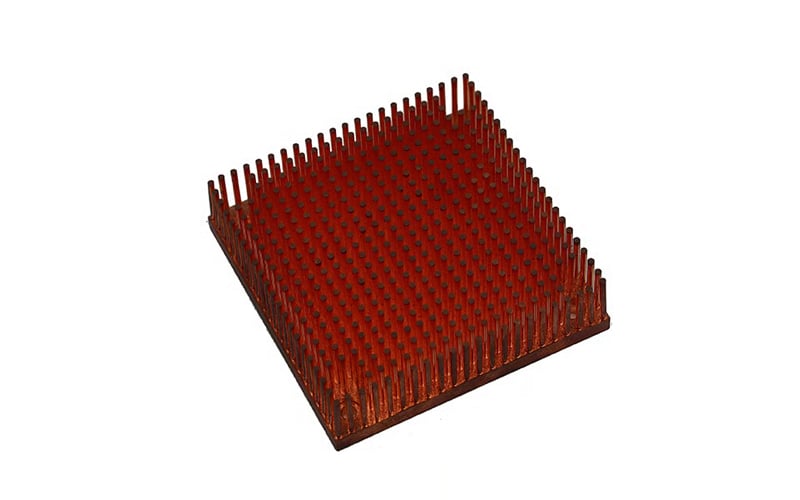

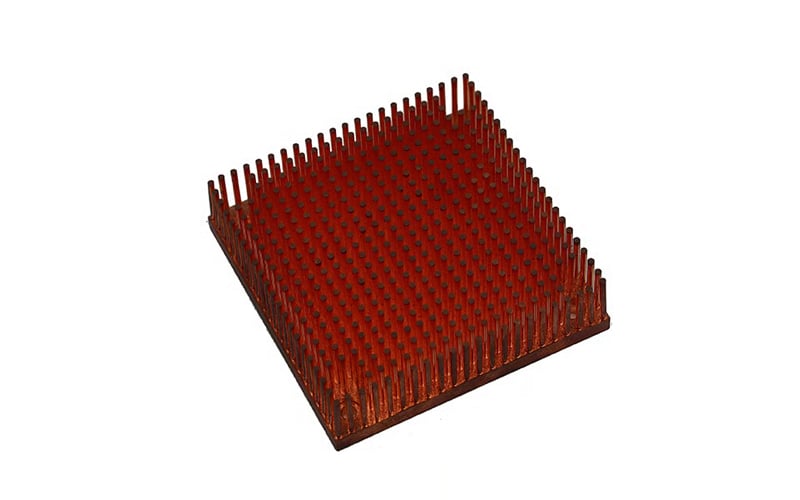

CNC Heat Sinks

CNC machining involves cutting a solid piece of aluminum into the required shape using a computer-controlled machine. This method offers superior precision and allows for intricate designs to maximize heat dissipation. While CNC heat sinks may be more expensive to produce compared to extrusion, they offer better thermal performance and can be customized for specific applications.

Cost Comparison

Extrusion heat sinks are generally more cost-effective for large volume production due to lower setup costs and faster manufacturing times. On the other hand, CNC heat sinks are better suited for low to medium volume production where precision and customization are prioritized over cost savings.

Thermal Efficiency

When it comes to thermal performance, CNC heat sinks have the upper hand due to their ability to create intricate fin designs that optimize heat dissipation. Extrusion heat sinks may struggle to achieve the same level of efficiency, especially in compact or high-power applications where heat management is critical.

Design Flexibility

Extrusion heat sinks are limited in terms of design flexibility compared to CNC heat sinks. While extrusion can produce basic shapes efficiently, CNC machining allows for complex geometries and fine details to be incorporated into the heat sink design. This versatility is ideal for applications where space is limited or unconventional shapes are required.

Lead Time

Extrusion heat sinks typically have shorter lead times compared to CNC heat sinks due to the simplicity of the manufacturing process. For projects with tight deadlines or urgent requirements, extrusion may be the more practical choice. However, if customizations and precise specifications are non-negotiable, CNC machining is worth the longer wait time.

Material Considerations

Both extrusion and CNC heat sinks are commonly made from aluminum for its lightweight and excellent thermal conductivity. However, CNC machining allows for the use of a wider range of materials such as copper or brass, which may offer better thermal performance in certain applications compared to aluminum.

Environmental Impact

Extrusion heat sinks are known for their efficiency in material utilization and minimal waste generation, making them a more sustainable choice for environmentally conscious projects. CNC machining, while precise, may produce more waste material during the manufacturing process, resulting in higher environmental impact.

Conclusion

In conclusion, the choice between extrusion and CNC heat sinks ultimately depends on the specific requirements of your project. If you prioritize cost efficiency and production speed, extrusion may be the way to go. However, if thermal performance and design customization are top priorities, CNC machining offers superior capabilities. By understanding the pros and cons of each method, you can make an informed decision to optimize heat management in your applications.

Quote Inquiry

contact us