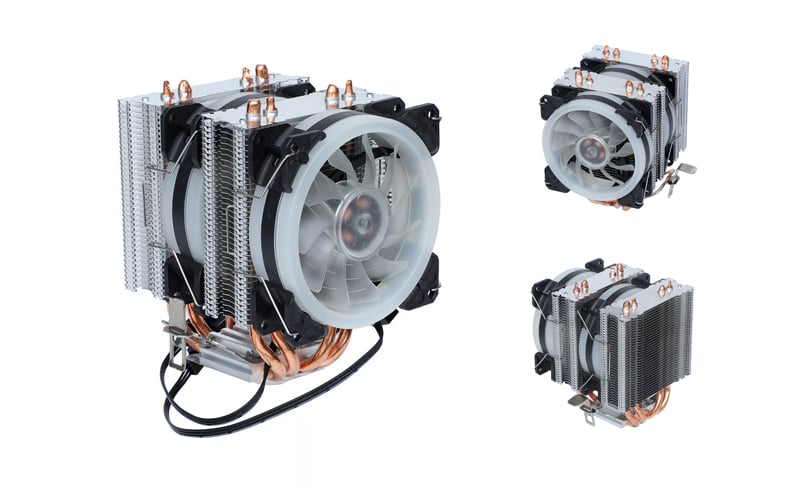

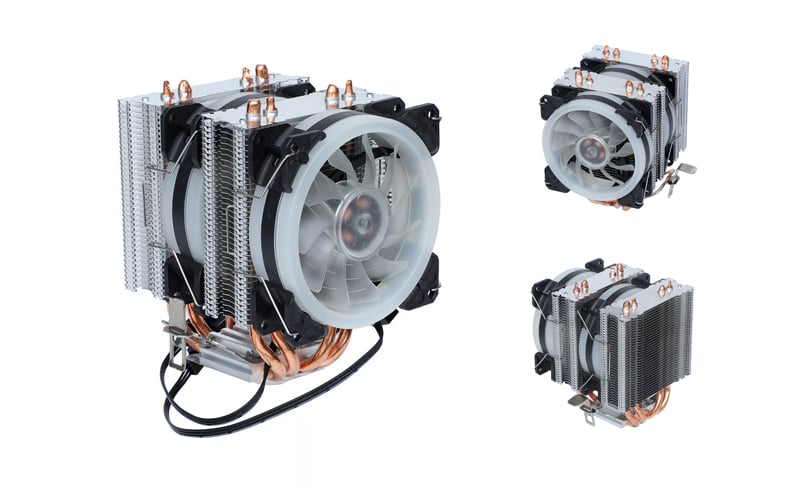

Custom machining for heat sinks is a process that involves creating specialized heat sink designs to effectively dissipate heat from electronic components. By customizing the size, shape, and materials used in the manufacturing process, businesses can optimize heat transfer and improve the performance of their devices.

Benefits of custom machining for heat sinks

There are numerous benefits to utilizing custom machining for heat sinks. These include enhanced thermal performance, improved energy efficiency, and increased reliability of electronic devices. By customizing heat sink designs, manufacturers can tailor the solution to meet the specific needs of their products.

Materials used in custom heat sinks

Custom heat sinks can be manufactured using a variety of materials, including aluminum, copper, and brass. Each material offers different thermal conductivity properties, allowing businesses to choose the best option based on their specific requirements. Aluminum is a popular choice for its lightweight and cost-effective properties, while copper is known for its superior heat dissipation capabilities.

The custom machining process

The custom machining process for heat sinks involves several steps, including design, prototyping, and production. Businesses can work with experienced manufacturers to create a customized heat sink solution that meets their exact specifications. By utilizing advanced machining techniques, companies can achieve precise and efficient heat sink designs.

Factors to consider when designing custom heat sinks

When designing custom heat sinks, it is important to consider factors such as thermal resistance, airflow, and space constraints. By optimizing these variables, businesses can create heat sink solutions that effectively dissipate heat and improve the overall performance of their electronic devices. Custom machining allows for flexibility and creativity in design.

Applications of custom heat sinks

Custom heat sinks are used in a wide range of industries, including electronics, automotive, and aerospace. These specialized heat dissipation solutions are essential for high-powered electronic components that generate significant heat. By customizing heat sink designs, businesses can ensure optimal thermal management in their products.

Custom machining vs. standard heat sinks

Custom machining offers several advantages over standard heat sinks, including better performance, increased efficiency, and a tailored solution for specific requirements. While standard heat sinks may be suitable for some applications, custom machining provides a more personalized and effective thermal management solution.

Choosing the right custom machining partner

When selecting a custom machining partner for heat sinks, it is important to consider factors such as experience, expertise, and reliability. Businesses should choose a manufacturer with a proven track record in producing high-quality heat sink solutions that meet industry standards. By working with a reputable partner, companies can ensure optimal performance and efficiency.

The cost of custom machining for heat sinks

The cost of custom machining for heat sinks can vary depending on the complexity of the design, materials used, and quantity required. While custom solutions may have a higher upfront cost compared to standard heat sinks, the long-term benefits in terms of performance and energy efficiency can outweigh the initial investment. By investing in custom machining, businesses can achieve significant cost savings in the long run.

Conclusion

In conclusion, custom machining for heat sinks is a valuable process that offers numerous benefits for businesses looking to optimize thermal management in their electronic devices. By customizing heat sink designs, manufacturers can improve performance, reliability, and energy efficiency. Choosing the right custom machining partner is essential to achieving the desired results and maximizing the potential of custom heat sink solutions.

Quote Inquiry

contact us