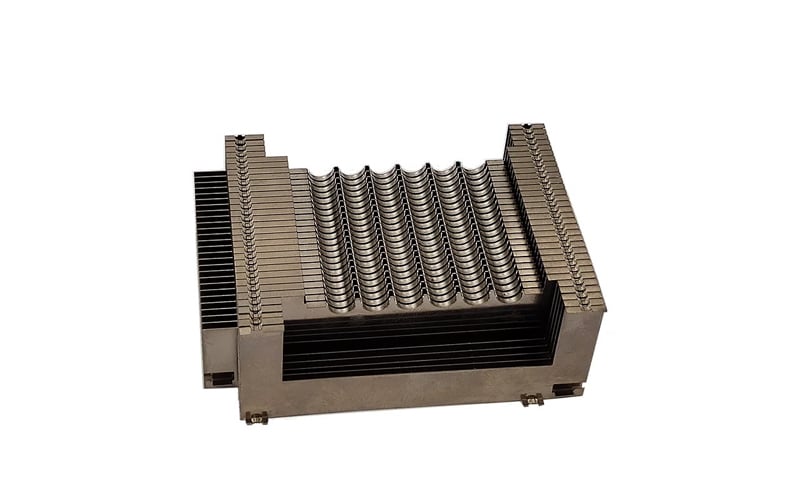

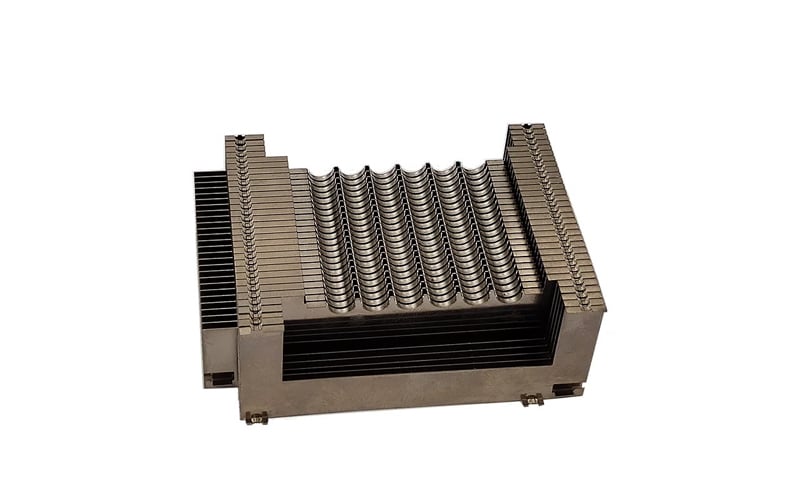

Stamping heat sink manufacturing is a process where heat sinks are produced using stamping machines. These machines use a specific mold to stamp out the shape of the heat sink from a sheet of metal, typically aluminum or copper.

Benefits of Stamping Heat Sink Manufacturing

Stamping heat sink manufacturing offers several benefits, including cost-effectiveness, quick turnaround times, and the ability to create intricate designs. This method is often used for high volume production due to its efficiency.

Materials Used in Stamping Heat Sink Manufacturing

The most common materials used in stamping heat sink manufacturing are aluminum and copper. These metals are preferred due to their high thermal conductivity, which allows for efficient heat dissipation.

The Stamping Process

In the stamping process, a sheet of metal is fed into the stamping machine, where a die and punch set create the shape of the heat sink by applying pressure. This process can be repeated to create multiple heat sinks in a short amount of time.

Customization Options

Stamping heat sink manufacturing allows for a high level of customization. Manufacturers can create heat sinks in various shapes and sizes to meet the specific requirements of their clients. This versatility makes stamping a popular choice in the industry.

Quality Control in Stamping Heat Sink Manufacturing

Quality control is essential in stamping heat sink manufacturing to ensure that the final products meet industry standards. Manufacturers use techniques such as inspections and testing to guarantee the quality of the heat sinks before they are shipped out.

Applications of Stamping Heat Sink Manufacturing

Stamping heat sink manufacturing is used in a wide range of industries, including electronics, automotive, and aerospace. Heat sinks are essential components for cooling electronic devices and machinery, making stamping a crucial manufacturing process.

Environmental Considerations

Stamping heat sink manufacturing is known for its eco-friendly properties. The process generates minimal waste, and the materials used are recyclable. This makes stamping an environmentally sustainable option for heat sink production.

Future Trends in Stamping Heat Sink Manufacturing

As technology advances, the future of stamping heat sink manufacturing looks promising. Innovations in materials and processes are expected to further improve the efficiency and effectiveness of heat sink production through stamping.

Choosing the Right Manufacturer

When looking for a manufacturer for stamping heat sink manufacturing, it is essential to consider factors such as experience, capabilities, and quality standards. Working with a reputable manufacturer can ensure that you receive high-quality heat sinks that meet your specifications.

Quote Inquiry

contact us