Understanding Skived Fins

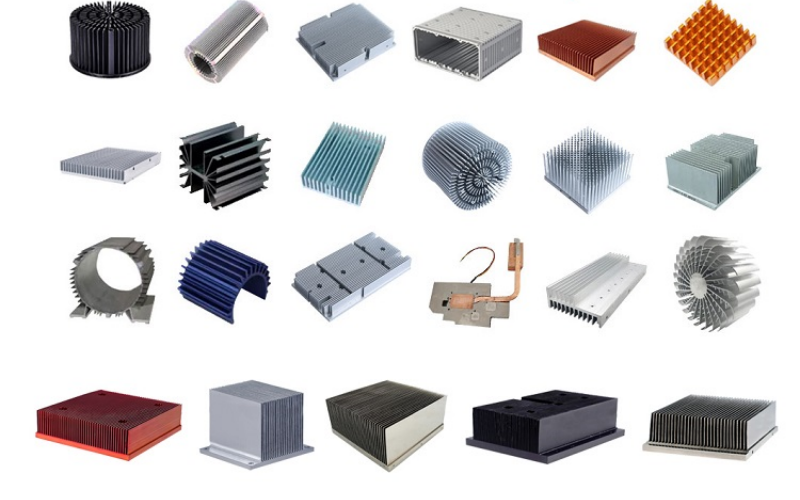

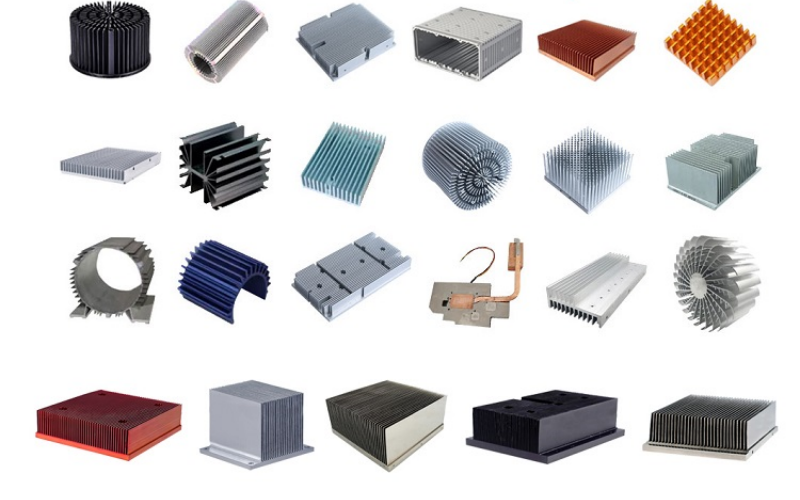

Skived fins are a type of heat sink component that is commonly used in electronic devices to dissipate heat. These fins are typically made from aluminum or copper and are designed with thin, closely-spaced fins that help to increase the surface area for heat dissipation.

Thermal Conductivity of Skived Fins

The thermal conductivity of skived fins plays a crucial role in determining their effectiveness in dissipating heat. Materials with high thermal conductivity, such as copper, are preferred for skived fins as they allow for efficient heat transfer from the electronic device to the surrounding environment.

Heat Dissipation Efficiency

The heat dissipation efficiency of skived fins is dependent on various factors, including the material used, the fin geometry, and the airflow around the fins. Proper design and optimization of these factors are essential to ensure effective heat dissipation and prevent overheating of electronic components.

Enhancing Thermal Performance

There are several ways to enhance the

Thermal performance of skived fins, such as increasing the number of fins, improving the surface finish of the fins, and enhancing airflow through the fins. These optimizations can help to maximize heat dissipation and improve overall device reliability.

Comparison with Other Cooling Methods

Skived fins are often compared with other cooling methods, such as heat pipes and liquid cooling systems. While these alternative methods may offer higher heat dissipation capabilities, skived fins are preferred for their simplicity, cost-effectiveness, and reliability in many electronic applications.

Applications of Skived Fins

Skived fins are commonly used in a wide range of electronic devices, including computer processors, LED lights, power supplies, and automotive components. Their compact design and high heat dissipation efficiency make them an ideal choice for cooling critical components in these applications.

Thermal Resistance and Conductance

The thermal resistance and thermal conductance of skived fins are important parameters that determine their overall thermal performance. Lower thermal resistance and higher thermal conductance values indicate better heat dissipation capabilities and improved thermal management in electronic devices.

Effect of Fin Thickness

The thickness of the fins in skived fins plays a significant role in their thermal performance. Thinner fins allow for better heat transfer and increased surface area, while thicker fins may lead to reduced heat dissipation efficiency. Design considerations should take into account the optimal fin thickness for the specific application.

Optimizing Fin Spacing

The spacing between fins in skived fins is another critical factor that affects their thermal performance. Closer fin spacing can increase the surface area for heat dissipation but may also restrict airflow, while wider fin spacing may reduce heat transfer efficiency. Finding the right balance is essential for optimal thermal performance.

Future Trends in Skived Fin Technology

As electronic devices continue to become more powerful and compact, the demand for efficient cooling solutions such as skived fins is expected to grow. Future trends in skived fin technology may focus on advanced materials, innovative fin designs, and enhanced thermal management techniques to meet the evolving needs of the electronics industry.

Quote Inquiry

contact us