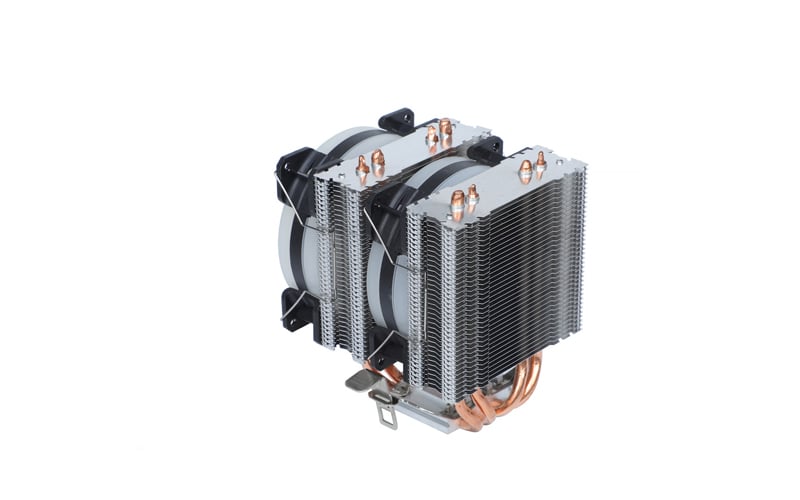

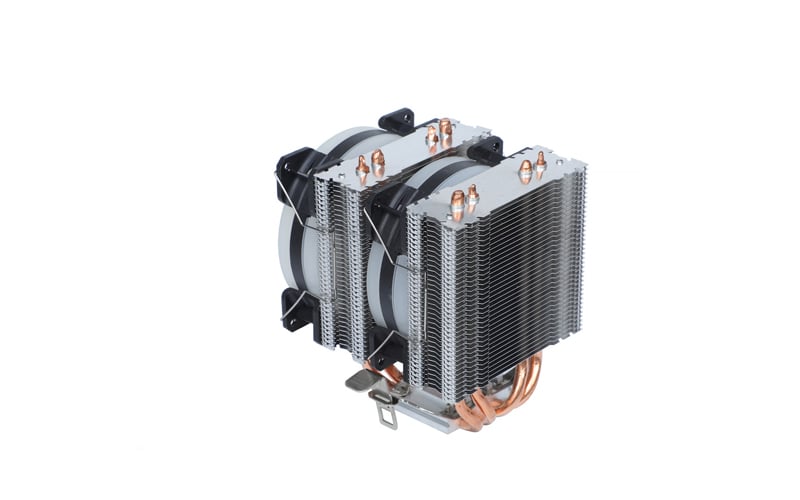

Enhancing Thermal Conductivity

surface treatment for heat sinks is essential for enhancing the thermal conductivity of the material. By applying coatings or finishes that have high thermal conductivity properties, heat sinks can more effectively dissipate heat and prevent overheating in electronic devices.

Improving Corrosion Resistance

Heat sinks are often exposed to harsh environments that can lead to corrosion over time. Surface treatments such as anodizing or chemical conversion coatings can provide a protective layer that improves the heat sink's resistance to corrosion, extending its lifespan.

Enhancing Aesthetic Appeal

In addition to improving functionality, surface treatments can also enhance the aesthetic appeal of heat sinks. Various finishes such as powder coating or electroplating can be applied to give heat sinks a polished and professional look that is suitable for consumer-facing electronics.

Reducing Oxidation

Oxidation can degrade the performance of heat sinks over time, reducing their effectiveness in dissipating heat. Surface treatments like passivation or chromate conversion coatings can prevent oxidation and maintain the heat sink's thermal performance over the long term.

Ensuring Compatibility with Other Components

Surface treatment can also ensure that heat sinks are compatible with other components in the electronic system. By applying coatings that are compatible with soldering or bonding processes, manufacturers can streamline assembly and improve the overall performance of the device.

Increasing Durability

Heat sinks are subjected to mechanical stresses and exposure to high temperatures, which can lead to wear and tear over time. Surface treatments that enhance the hardness and durability of the material can prolong the heat sink's lifespan and improve its reliability in demanding applications.

Enhancing Electrical Insulation

In some electronic applications, it is important for heat sinks to provide electrical insulation to prevent short circuits or electrical interference. Surface treatments like anodizing or ceramic coatings can enhance the electrical insulation properties of the heat sink.

Optimizing Surface Roughness

Surface roughness plays a crucial role in the efficiency of heat transfer from the electronic component to the heat sink. Surface treatments can be used to optimize the surface roughness of the heat sink, ensuring maximum contact area and improving thermal performance.

Enabling Heat Sink Customization

Surface treatments offer a wide range of customization options for heat sinks, allowing manufacturers to tailor the finish, color, and texture to meet specific design requirements. This flexibility enables the creation of unique heat sink solutions for different applications.

Improving Manufacturing Efficiency

By incorporating surface treatment processes into the manufacturing workflow, manufacturers can improve efficiency and reduce manufacturing costs. Surface treatments can be applied in a controlled and automated manner, ensuring consistency and quality in the production of heat sinks.

Quote Inquiry

contact us