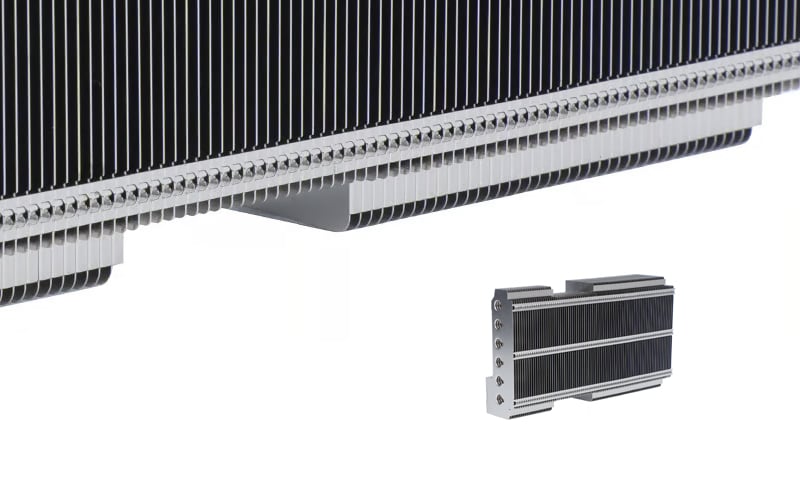

When it comes to thermal management in electronic devices, the thickness of the heat sink metal plays a crucial role. Heat sink metal thickness refers to the measurement of how thick the material of the heat sink is. This parameter is essential in determining the heat dissipation capabilities of the heat sink.

Impact of Metal Thickness on Heat Dissipation

The thickness of the heat sink metal directly affects its thermal conductivity. Thicker metal can typically dissipate heat more efficiently than thinner metal. This is because thicker metal allows for better transfer of heat from the source to the heat sink, leading to improved cooling performance.

Efficiency and Effectiveness

A thicker heat sink metal provides better stability and support for the cooling system. It can effectively absorb and transfer heat away from the electronic components, preventing overheating and potential damage. This ensures the efficient operation of the device over an extended period.

Thermal Resistance and Conductivity

Thicker heat sink metal reduces thermal resistance, allowing for faster heat dissipation. The high thermal conductivity of thicker metal helps in spreading the heat evenly across the surface of the heat sink, maximizing its cooling capabilities. This leads to better temperature regulation and overall system performance.

Material Selection for Heat Sink Metal Thickness

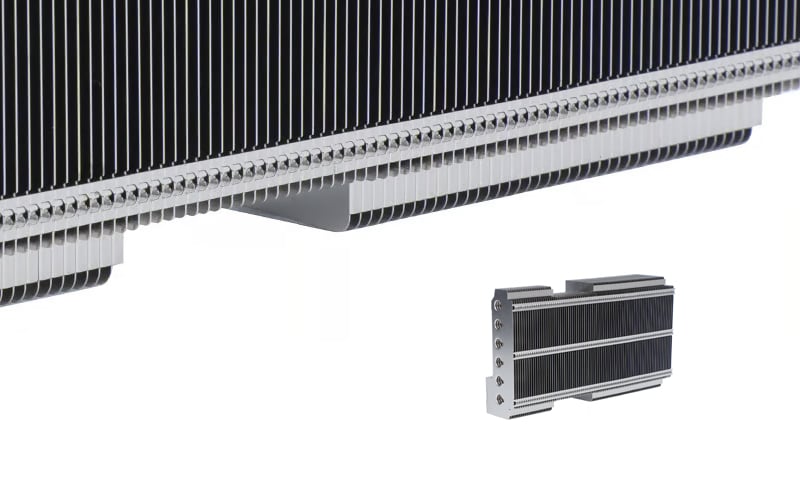

When choosing the metal for a heat sink, it is essential to consider the thickness of the material. Metals like copper and aluminum are commonly used in heat sinks due to their high thermal conductivity. The thickness of these metals can vary based on the specific cooling requirements of the device.

Optimizing Thermal Management

By carefully selecting the appropriate metal thickness for a heat sink, designers can optimize the thermal management of electronic devices. Factors such as the power dissipation of the components, operating environment, and size constraints should be considered to determine the ideal thickness for the heat sink.

Benefits of Thicker Metal in Heat Sinks

Thicker heat sink metal offers better heat dissipation capabilities, improved thermal performance, and enhanced reliability. It can effectively lower the operating temperature of electronic devices, extending their lifespan and reducing the risk of malfunction due to overheating.

Challenges in Heat Sink Design

Designing a heat sink with the right metal thickness can be challenging, as it involves striking a balance between cost, performance, and physical constraints. Engineers must carefully analyze the thermal requirements of the device and select the optimal metal thickness to meet those requirements.

Future Trends in Heat Sink Technology

Advancements in material science and manufacturing techniques are driving innovations in heat sink technology. Thinner yet highly efficient heat sink metals are being developed to meet the increasing demand for compact and powerful electronic devices. These advancements will continue to improve thermal management in the future.

Conclusion

In conclusion, heat sink metal thickness is a critical factor in thermal management, impacting the efficiency, effectiveness, and performance of electronic devices. By understanding the importance of metal thickness and its implications on heat dissipation, designers can enhance the cooling capabilities of heat sinks and optimize the overall system performance.

Quote Inquiry

contact us