Introduction

Additive manufacturing, also known as 3D printing, has revolutionized the way products are designed and manufactured. In the realm of cold plate design, this technology has opened up new possibilities for improved performance and efficiency.

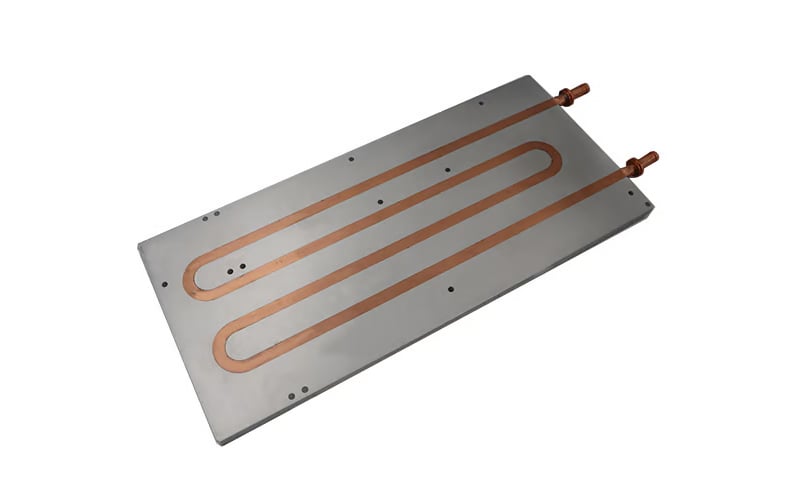

Enhanced Heat Transfer

One of the key advantages of Additive Manufacturing in Cold Plate Design is the ability to create intricate geometries that optimize heat transfer. By incorporating complex cooling channels and structures, designers can achieve higher levels of thermal efficiency.

Customization and Flexibility

Additive manufacturing allows for a high degree of customization and flexibility in cold plate design. Manufacturers can easily modify designs to meet specific requirements and adapt to changing needs, leading to more efficient cooling solutions.

Reduced Weight and Material Usage

By utilizing additive manufacturing, designers can create lightweight cold plates that still maintain high heat transfer capabilities. This not only reduces the overall weight of the system but also minimizes material waste.

Cost-Effective Production

The use of additive manufacturing in cold plate design can streamline the production process and reduce costs. With the ability to quickly prototype and iterate designs, manufacturers can bring products to market faster and more efficiently.

Improved Performance and Reliability

Additive manufacturing enables designers to create cold plates with optimized performance and reliability. By fine-tuning the design parameters, such as surface roughness and channel geometry, manufacturers can achieve higher levels of efficiency.

Environmental Sustainability

With additive manufacturing, cold plate designers can minimize environmental impact by reducing material waste and energy consumption during the manufacturing process. This aligns with the growing focus on sustainability in the industry.

Integration with Advanced Materials

Additive manufacturing allows for the integration of advanced materials into cold plate designs, such as composite materials and metal alloys. This expands the possibilities for enhanced thermal management solutions.

Design Complexity and Innovation

The use of additive manufacturing in cold plate design enables designers to push the boundaries of traditional manufacturing techniques. Complex geometries and innovative designs can be realized, leading to breakthroughs in thermal management.

Future Outlook

As additive manufacturing continues to evolve, the impact on cold plate design will only grow. The combination of customization, efficiency, and cost-effectiveness will drive the adoption of this technology in creating next-generation cooling solutions.