Introduction

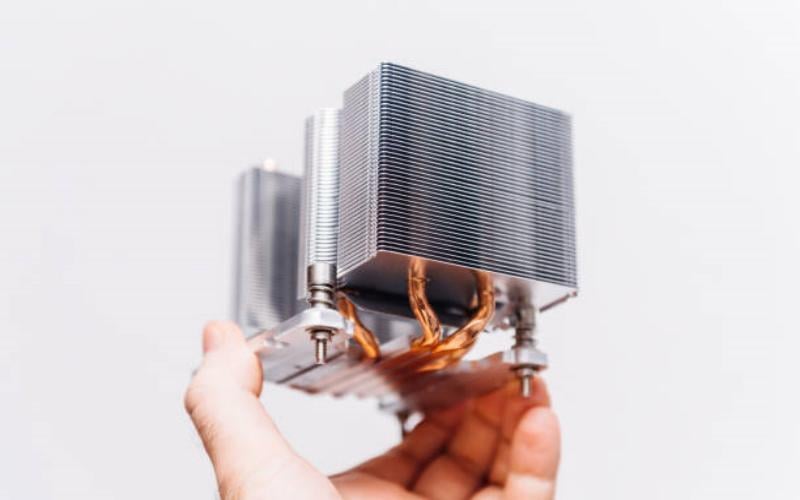

A skived fin heat sink is a crucial component in many electronic devices, as it helps dissipate heat and maintain optimal operating temperatures. This article delves into the various Benefits of skived fin heat sinks, highlighting their effectiveness in cooling and improving the performance and reliability of electronic devices.

Enhanced Heat Dissipation

One of the primary advantages of skived fin heat sinks is their ability to enhance heat dissipation. These heat sinks are designed with thin, closely spaced fins that increase the surface area available for heat transfer. This larger surface area allows for more efficient heat dissipation, ensuring that electronic components stay within their temperature limits.

Improved Cooling Efficiency of Skived Fin Heat Sink

Skived fin heat sinks are specifically engineered to optimize cooling efficiency. The skiving process involves cutting thin fins into a solid base material, which creates a larger number of fins compared to traditional heat sinks. This increased fin density enables better airflow and heat transfer, resulting in improved cooling performance.

Compact and Lightweight Design

Skived fin heat sinks are known for their compact and lightweight design, making them ideal for applications with limited space or weight restrictions. The manufacturing process allows for precise control over the fin shape and size, resulting in a highly efficient cooling solution that takes up minimal space within the electronic device.

Enhanced Thermal Conductivity

The skiving process used in the production of these heat sinks typically involves using materials with high thermal conductivity, such as copper or aluminum. This ensures effective heat transfer from the heat-generating component to the fins, allowing the heat sink to efficiently dissipate the thermal energy and prevent overheating.

Versatility in Design of Skived Fin Heat Sink

Skived fin heat sinks offer versatility in design, enabling customization to meet specific cooling requirements. Manufacturers can adjust the fin thickness, height, and spacing to optimize the heat sink's performance for different electronic devices and applications. This flexibility allows for efficient cooling in various industries, including telecommunications, automotive, and aerospace.

Reduced Thermal Resistance

The closely spaced fins of skived fin heat sinks contribute to reducing thermal resistance. By minimizing the air gaps between the fins, these heat sinks facilitate better airflow and enhance convective heat transfer. As a result, the overall thermal resistance is significantly reduced, improving the cooling efficiency and extending the lifespan of electronic components.

Longevity and Reliability of Skived Fin Heat Sink

Skived fin heat sinks are designed to withstand demanding operating conditions and provide long-term reliability. The skiving process ensures a strong bond between the fins and the base material, preventing loosening or detachment of the fins over time. This structural integrity contributes to the heat sink's longevity and ensures consistent cooling performance.

Cost-Effective Solution

In addition to their technical advantages, skived fin heat sinks offer a cost-effective cooling solution. The skiving process allows for efficient production, reducing material waste and manufacturing time. This translates to lower production costs, making skived fin heat sinks an economical choice for both small-scale and large-scale production.

Environmental Friendliness of Skived Fin Heat Sink

Skived fin heat sinks are environmentally friendly due to their efficient cooling capabilities. By effectively dissipating heat and preventing electronic devices from overheating, these heat sinks contribute to energy conservation and reduce the need for additional cooling mechanisms. This energy efficiency translates into a smaller carbon footprint and a greener approach to electronic device cooling.