Introduction

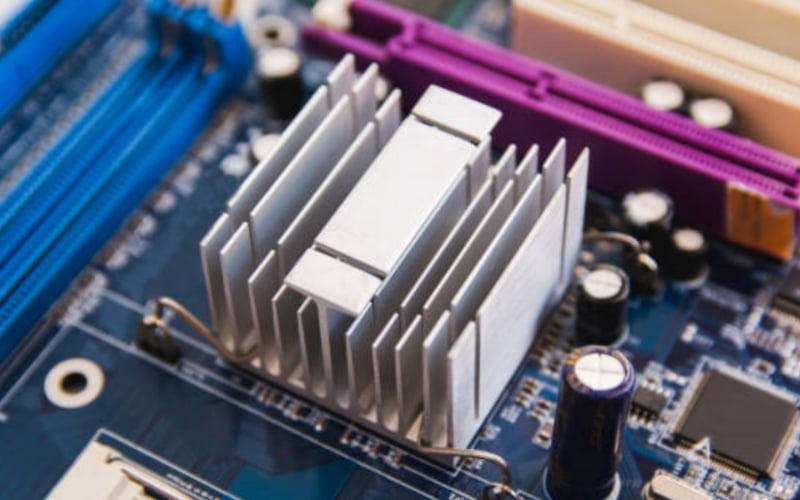

Extrusion heat sinks play a crucial role in dissipating heat from electronic devices, ensuring their optimal performance and longevity. With their excellent thermal conductivity and lightweight design, these heat sinks are widely used in various industries. In this article, we will explore the numerous Benefits of extrusion heat sinks and highlight their importance in modern electronic systems.

1. Enhanced Heat Dissipation

One of the key advantages of extrusion heat sinks is their ability to efficiently dissipate heat. These heat sinks are designed with a large surface area and optimized fin geometry, which facilitates the transfer of heat from the electronic components to the surrounding air. By effectively removing heat, extrusion heat sinks prevent overheating and ensure the stability and reliability of electronic devices.

2. Improved Thermal Conductivity of Extrusion Heat Sink

Extrusion heat sinks are typically made of materials with high thermal conductivity, such as aluminum or copper. These materials have excellent heat transfer properties, allowing them to rapidly conduct heat away from the heat source. This property ensures that the heat generated by electronic components is efficiently dissipated, preventing performance degradation and potential damage.

3. Lightweight and Compact Design

Compared to other types of heat sinks, extrusion heat sinks offer a lightweight and compact design. This advantage is particularly valuable in applications where space is limited or weight restrictions are in place. The streamlined design of extrusion heat sinks allows for easy integration into electronic systems without adding unnecessary bulk or weight.

4. Versatility and Customizability

Extrusion heat sinks can be manufactured in a wide range of shapes and sizes, making them highly versatile and customizable. This flexibility enables engineers to design heat sinks that precisely fit the requirements of specific electronic devices or systems. By tailoring the design to the application, the heat dissipation efficiency can be optimized, resulting in improved overall performance.

5. Cost-Effective Solution of Extrusion Heat Sink

Extrusion heat sinks offer a cost-effective solution for thermal management in electronic systems. The manufacturing process for extrusion heat sinks is relatively simple and efficient, resulting in lower production costs compared to other heat sink technologies. Additionally, their lightweight design reduces shipping costs, making them an economical choice for both manufacturers and end-users.

6. Easy Installation

Installing extrusion heat sinks is a straightforward process, requiring minimal effort and time. The heat sinks are designed with pre-drilled mounting holes or adhesive options, allowing for easy attachment to electronic devices. This ease of installation not only saves time during manufacturing but also simplifies maintenance and upgrades, minimizing downtime in electronic systems.

7. Longevity and Reliability of Extrusion Heat Sink

Extrusion heat sinks are built to withstand demanding operating conditions and provide long-lasting performance. The high-quality materials used in their construction ensure durability and resistance to corrosion, ensuring that the heat sinks can effectively dissipate heat over an extended period. This reliability is crucial for electronic systems that operate continuously or in harsh environments.

8. Noise Reduction

Heat dissipation can generate noise, especially in systems with fans or other cooling mechanisms. Extrusion heat sinks help reduce noise levels by efficiently dissipating heat without the need for additional cooling components. This benefit is particularly important in noise-sensitive environments, such as audio equipment or office settings, where quiet operation is desired.

9. Energy Efficiency

Efficient heat dissipation provided by extrusion heat sinks can contribute to overall energy efficiency in electronic systems. By maintaining lower operating temperatures, the energy consumption of electronic components can be reduced. This energy-saving attribute not only benefits the environment but also leads to cost savings for users in terms of lower electricity bills.

10. Wide Range of Applications

The benefits of extrusion heat sinks make them suitable for a wide range of applications across various industries. From consumer electronics and automotive systems to telecommunications and industrial equipment, extrusion heat sinks are essential in managing heat and ensuring the reliable operation of electronic devices. Their versatility and effectiveness make them a preferred choice for engineers and designers.