Efficiency

Cold Plate Integration in Battery Packs enhances efficiency by providing a direct cooling mechanism to the batteries. This cooling system helps in maintaining optimal operating temperatures, leading to improved performance and longevity of the batteries.

Thermal Management

One of the key advantages of cold plate integration is effective thermal management. By dissipating heat generated during battery operation, cold plates prevent overheating and ensure stable performance. This feature is crucial in high-demand applications where temperature control is essential.

Extended Battery Life

Cold plate integration can significantly extend the lifespan of battery packs. By maintaining consistent temperatures and reducing heat stress, cold plates help in preserving the overall health of the batteries. This results in longer-lasting and more reliable power sources.

Fast Charging

Cold plate integration facilitates faster charging times for battery packs. The cooling system enables rapid heat dissipation during charging cycles, allowing for quicker recharging without compromising the battery's integrity. This feature is particularly beneficial in time-sensitive applications.

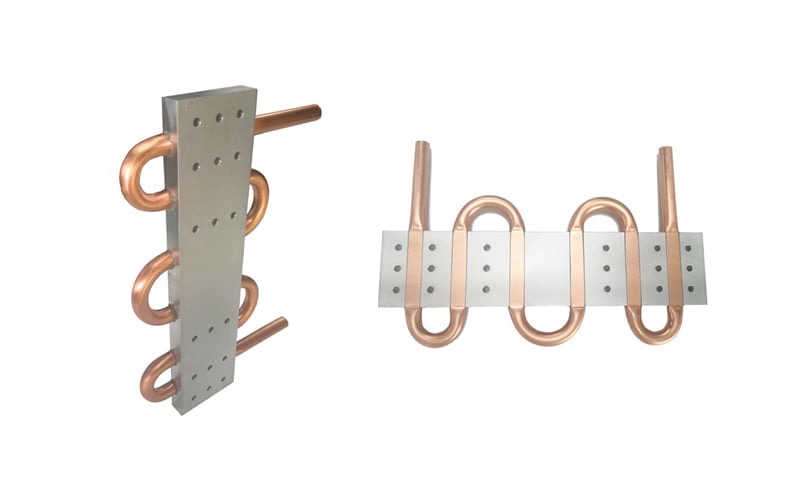

Compact Design

Cold plates offer a space-saving solution for integrating cooling systems into battery packs. Their compact design allows for efficient use of space within the pack, making them ideal for applications where size and weight are critical factors.

Customization Options

Manufacturers can customize cold plate integration to meet specific requirements of different battery pack designs. This flexibility in design allows for tailored solutions that optimize performance and efficiency in various applications.

Environmental Sustainability

Cold plate integration contributes to environmental sustainability by promoting energy efficiency and reducing waste. By maintaining optimal operating temperatures, cold plates help in conserving energy and minimizing the environmental impact of battery pack usage.

Enhanced Safety

The cooling effect provided by cold plates enhances the safety of battery packs by preventing overheating and potential thermal runaway. This added layer of protection is crucial in applications where safety is a top priority, such as in electric vehicles or industrial settings.

Cost-Effectiveness

In the long run, cold plate integration can prove to be a cost-effective solution for battery packs. By extending the lifespan of batteries and reducing the need for frequent replacements or repairs, cold plates help in saving maintenance costs and enhancing overall economic value.

Future Development

As technology advances, cold plate integration in battery packs is expected to evolve further. Innovations in materials and design techniques will continue to enhance the efficiency and performance of cold plate systems, making them an indispensable component in the future of battery technology.