What is CFD Analysis?

In the world of engineering and design, Computational Fluid Dynamics (CFD) analysis plays a crucial role in predicting the behavior of fluids and gases in various applications. This powerful tool utilizes numerical analysis and algorithms to simulate the flow of fluids and gases in real-world scenarios.

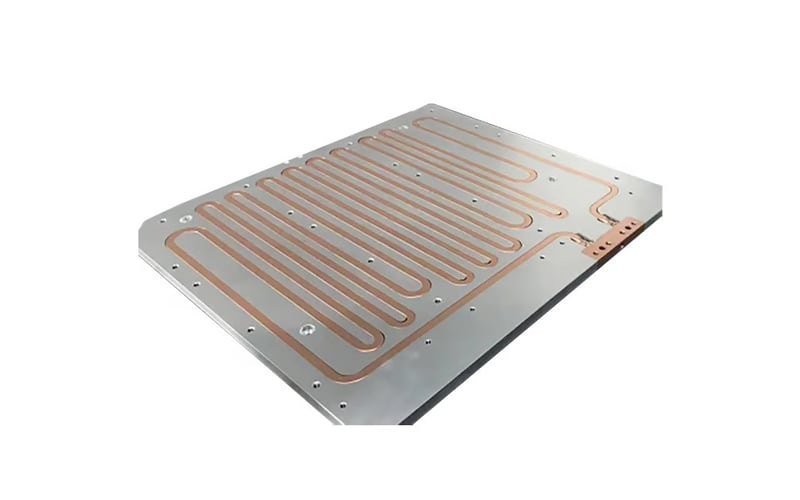

Importance of Cold Plate Optimization

Cold plates are essential components in electronic devices and systems, designed to dissipate heat efficiently to prevent overheating. Optimizing the design of cold plates is crucial for maximizing cooling efficiency and enhancing the overall performance and longevity of electronic systems.

How CFD Analysis Benefits Cold Plate Optimization

By leveraging CFD analysis, engineers and designers can gain valuable insights into the thermal performance of cold plates. This technology allows for the visualization of fluid flow patterns, temperature distribution, and heat transfer within the cold plate, enabling the optimization of its design for maximum cooling effectiveness.

Enhanced Thermal Management

CFD analysis enables engineers to accurately predict and analyze the thermal behavior of cold plates, helping them identify areas of inefficiency and optimize the design to enhance heat transfer and thermal management. By fine-tuning the geometry and materials used in cold plates, thermal performance can be significantly improved.

Optimizing Flow Distribution

One of the key benefits of CFD Analysis for Cold Plate Optimization is the ability to optimize flow distribution within the plate. By simulating fluid flow and heat transfer processes, engineers can identify areas of stagnation or uneven distribution and make design adjustments to improve the overall flow patterns for enhanced cooling efficiency.

Reduced Time and Cost

Utilizing CFD analysis for cold plate optimization can help streamline the design process and reduce the need for costly physical prototypes and testing. By simulating different design scenarios virtually, engineers can quickly iterate and refine the cold plate design, ultimately saving time and resources in the product development phase.

Improving Energy Efficiency

Efficient thermal management is essential for reducing energy consumption in electronic devices. CFD analysis allows engineers to fine-tune the design of cold plates to maximize cooling efficiency, ultimately leading to lower energy consumption and operational costs in electronic systems.

Enhancing Reliability and Performance

By optimizing cold plate design through CFD analysis, engineers can improve the reliability and performance of electronic systems. Enhanced thermal management ensures that components operate within safe temperature limits, reducing the risk of overheating and premature failure, thus increasing the overall lifespan of the device.

Future Applications and Innovations

As CFD technology continues to advance, the capabilities for optimizing cold plate design will only grow. Future applications may include predictive modeling for new materials, advanced heat transfer mechanisms, and the integration of smart cooling systems to further enhance the efficiency and performance of electronic devices.

Conclusion

In conclusion, CFD analysis provides a powerful tool for optimizing the design of cold plates in electronic systems. By leveraging this technology, engineers can enhance thermal management, improve energy efficiency, and increase the reliability and performance of electronic devices. With the continued advancements in CFD technology, the future looks bright for cold plate optimization and its impact on electronic system design.