Introduction

Heat management is a critical aspect in various industries, from electronics to automotive. One innovative solution that has gained prominence in recent years is the liquid cold plate heat sink. This advanced cooling technology offers several advantages over traditional air cooling methods. In this article, we will explore the various benefits of liquid cold plate heat sinks and understand why they are becoming increasingly popular in thermal management applications.

Enhanced Heat Dissipation of Liquid Cold Plate Heat Sink

One of the primary advantages of liquid cold plate heat sinks is their superior heat dissipation capabilities. Unlike air cooling methods that rely on convection, liquid cooling utilizes the high thermal conductivity of liquids to efficiently transfer heat away from the heat source. This results in significantly lower device temperatures and improved overall system performance.

Uniform Temperature Distribution

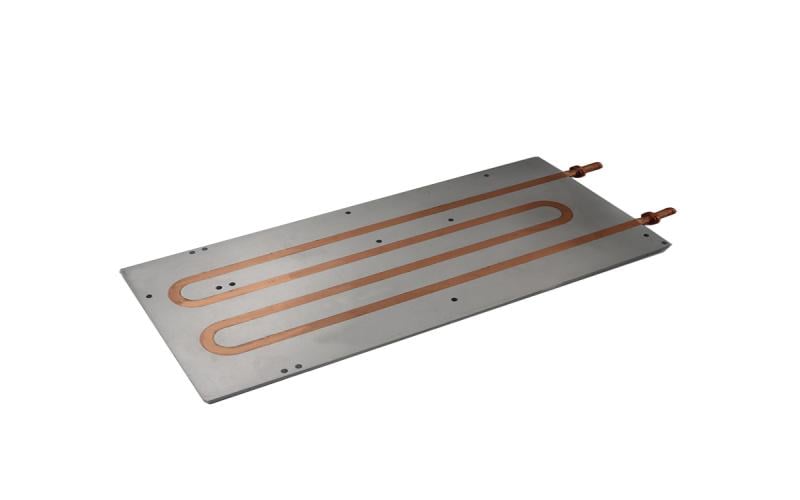

Another advantage of liquid cold plate heat sinks is their ability to provide a more uniform temperature distribution across the heat-generating components. The liquid coolant flows through a network of channels within the cold plate, ensuring that heat is evenly transferred from the hotspots to the cooler regions. This prevents localized overheating and minimizes the risk of thermal stress on sensitive components.

Flexibility in Design of Liquid Cold Plate Heat Sink

Liquid cold plate heat sinks offer greater design flexibility compared to traditional cooling solutions. The cold plates can be custom-designed to fit specific applications, allowing for efficient cooling of complex shapes and sizes. This versatility is particularly beneficial in industries where space constraints and unique form factors are common, such as aerospace and telecommunications.

Efficient Heat Transfer

Thanks to the direct contact between the liquid coolant and the heat source, liquid cold plate heat sinks enable highly efficient heat transfer. The thermal conductivity of liquids is significantly higher than that of air, resulting in faster and more effective heat dissipation. This can ultimately lead to improved system reliability and increased lifespan of electronic components.

Noise Reduction of Liquid Cold Plate Heat Sink

Compared to air cooling methods that often involve the use of fans, liquid cold plate heat sinks offer a quieter cooling solution. The absence of moving parts, such as fans, eliminates the associated noise generated by traditional cooling systems. This makes liquid cooling an ideal choice for applications where noise reduction is a critical requirement, such as medical equipment and audio devices.

Higher Heat Capacity

Liquid cold plate heat sinks have a higher heat capacity compared to air cooling solutions. This means they can handle higher power densities and dissipate greater amounts of heat without compromising on performance. This advantage makes liquid cooling an excellent choice for high-performance applications, such as power electronics and data centers, where effective heat management is crucial.

Improved System Reliability

By efficiently dissipating heat and maintaining lower operating temperatures, liquid cold plate heat sinks contribute to improved system reliability. Excessive heat can lead to accelerated component aging, reduced performance, and even system failures. The enhanced cooling provided by liquid cold plate heat sinks helps mitigate these risks, ensuring reliable operation even under demanding conditions.

Environmental Friendliness

Liquid cooling is often considered a more environmentally friendly alternative to air cooling. Liquid cold plate heat sinks require less energy to operate, as they do not rely on power-hungry fans. Additionally, liquid coolants used in these systems can be chosen to be non-toxic and non-hazardous, minimizing any potential environmental impact.

Cost-Effectiveness

While the initial investment in liquid cold plate heat sinks may be higher than traditional air cooling solutions, they often prove to be more cost-effective in the long run. The improved heat dissipation and reliability offered by liquid cooling can lead to reduced maintenance costs, extended component lifespan, and increased system efficiency, ultimately resulting in significant savings over time.