The Advantages Of Aluminum Extruded Heat Sinks

Aluminum Extruded Heat Sinks: An Introduction

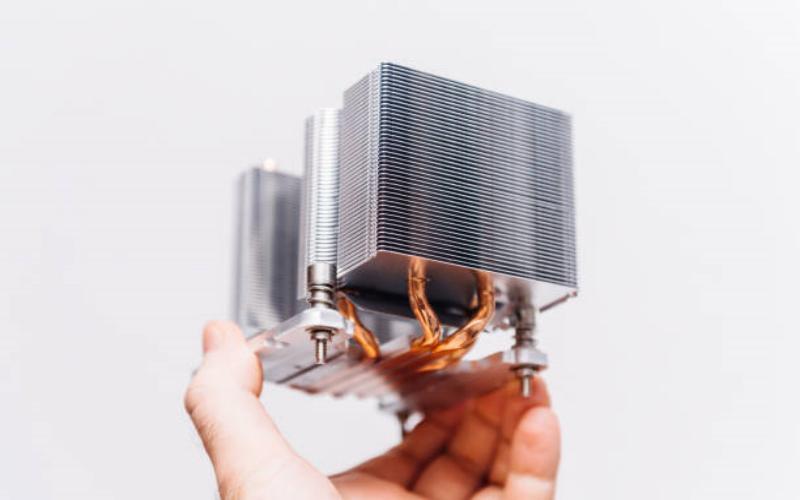

Heat sinks play a crucial role in managing the thermal dissipation of electronic devices. Among the various types of heat sinks available in the market, aluminum extruded heat sinks have gained significant popularity. These heat sinks are made from aluminum and are extruded into specific shapes to enhance their heat dissipation capabilities. In this article, we will explore the advantages of aluminum extruded heat sinks and why they are an excellent choice for cooling electronic devices.

1. Excellent Thermal Conductivity

One of the key advantages of aluminum extruded heat sinks is their excellent thermal conductivity. Aluminum is a highly conductive material, allowing heat to efficiently transfer from the heat source to the fins of the heat sink. This ensures that the electronic components remain cool, preventing overheating and potential damage.

2. Lightweight and Durable

Aluminum extruded heat sinks are not only known for their excellent thermal performance but also for being lightweight and durable. Aluminum is a lightweight material, making it an ideal choice for applications where weight reduction is important. Additionally, aluminum is highly resistant to corrosion, which extends the lifespan of the heat sink and ensures long-term reliability.

3. Versatile Design Options

Aluminum extruded heat sinks offer a wide range of design options, making them suitable for various applications. The extrusion process allows for complex shapes and intricate fin designs, maximizing the surface area for heat dissipation. This versatility enables heat sinks to be tailored to specific requirements, optimizing their cooling effectiveness.

4. Cost-Effective Solution

Compared to other materials like copper, aluminum is more cost-effective, making aluminum extruded heat sinks a budget-friendly choice. The extrusion process also helps in reducing manufacturing costs, making these heat sinks an economical solution for cooling electronic devices. The cost-effectiveness of aluminum extruded heat sinks makes them widely used in industries such as automotive, telecommunications, and consumer electronics.

5. Efficient Manufacturing Process

The manufacturing process of aluminum extruded heat sinks is highly efficient and can be easily scaled up for mass production. Extrusion allows for the production of heat sinks in various lengths, shapes, and sizes, enabling manufacturers to cater to different customer requirements. This efficiency in manufacturing translates into shorter lead times and cost savings for businesses.

6. Enhanced Heat Dissipation

The design of aluminum extruded heat sinks ensures enhanced heat dissipation capabilities. The fins of the heat sink increase the surface area, allowing for greater exposure to ambient air. This promotes efficient heat transfer, ensuring that the heat generated by electronic components is effectively dissipated, preventing performance degradation and potential failures.

7. Easy Customization and Installation

Aluminum extruded heat sinks can be easily customized and tailored to specific applications. Manufacturers can adjust the shape, size, and fin density of the heat sinks to meet the cooling requirements of different electronic devices. Additionally, these heat sinks are designed for easy installation, allowing for quick and hassle-free integration into electronic systems.

8. Electromagnetic Interference (EMI) Shielding

In addition to their excellent thermal properties, aluminum extruded heat sinks also provide electromagnetic interference (EMI) shielding. EMI can cause disturbances in electronic devices, affecting their performance. The conductivity of aluminum helps in diverting and dissipating electromagnetic waves, reducing the impact of EMI on sensitive electronic components.

9. Eco-Friendly Option

Aluminum is a highly recyclable material, making aluminum extruded heat sinks an eco-friendly choice. By using aluminum heat sinks, businesses can contribute to reducing environmental impact and promoting sustainability. Moreover, the energy required to produce aluminum extruded heat sinks is significantly lower compared to other materials, further emphasizing their eco-friendly nature.

10. Wide Range of Applications

Due to their numerous advantages, aluminum extruded heat sinks find applications in various industries. They are commonly used in power electronics, LED lighting, computer hardware, telecommunications equipment, automotive electronics, and more. The versatility and effectiveness of aluminum extruded heat sinks make them a preferred choice for cooling electronic devices across different sectors.

The Advantages Of Aluminum Extruded Heat Sinks, aluminum extruded heat sinks, thermal conductivity, lightweight, durable, versatile design, cost-effective, efficient manufacturing, heat dissipation, customization, installation, EMI shielding, eco-friendly, wide range of applications The Advantages Of Aluminum Extruded Heat Sinks | Key Benefits Explained Discover the advantages of aluminum extruded heat sinks and how they offer excellent thermal conductivity, lightweight design, versatility, cost-effectiveness, and more. Learn why aluminum extruded heat sinks are a preferred choice for cooling electronic devices.