Introduction to Heat Pipe Heat Sinks

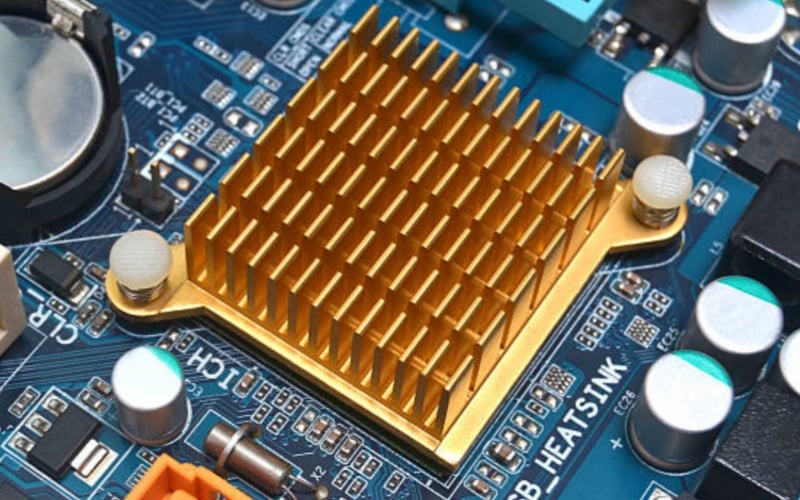

Heat Pipe Heat Sinks are becoming increasingly popular in applications that require efficient heat transfer. Heat sinks are designed to dissipate heat away from electronic components and devices, so they don't overheat and malfunction. Heat Pipe Heat Sinks take this concept a step further. They use a passive heat transfer process to move heat from a hot component to a cooler area of the heat sink. This technology boosts the thermal performance of heat sinks and improves the reliability and longevity of electronic devices.

1. How Heat Pipe Heat Sinks Work

Heat Pipe Heat Sinks operate on the principle of evaporation and condensation. Inside the heat pipe are small capillary wicks that draw a working fluid towards the hotter end of the pipe. As the working fluid reaches the hot end, it evaporates and transfers heat away from the component. The vapor then moves towards the cooler end of the pipe, where it condenses and releases the heat to the heat sink fins. The cooling fins dissipate the heat to the surrounding air, thereby reducing the temperature of the component.

2. Types of Heat Pipe Heat Sinks

There are two types of Heat Pipe Heat Sinks: Vapor Chamber Heat Sinks and Standard Heat Pipe Heat Sinks. Vapor Chamber Heat Sinks use a flat, thin chamber that contains a working fluid and a wick. The chamber is sealed and has a vacuum inside. When heat is applied to the chamber, the working fluid evaporates and diffuses across the chamber, where it condenses and transfers heat to the cooling fins. Standard Heat Pipe Heat Sinks are similar, but they have a cylindrical shape with a hollow core that contains a wick and working fluid. Both types of heat sinks are efficient, but Vapor Chamber Heat Sinks can transfer more heat faster.

3. Advantages of Heat Pipe Heat Sinks

Heat Pipe Heat Sinks have several advantages over traditional heat sinks:

- Higher thermal conductivity: Heat Pipe Heat Sinks are designed to transfer heat more efficiently than traditional heat sinks. They can transfer more heat with less material, resulting in a lighter and smaller heat sink.

- Uniform temperature distribution: Heat Pipe Heat Sinks can distribute heat uniformly across the surface of the heat sink, preventing hotspots and ensuring that all components stay within their safe operating temperature range.

- No moving parts: Heat Pipe Heat Sinks are passive devices that do not require any mechanical parts or energy input. This makes them more reliable and easier to maintain than active cooling systems.

- No noise: Heat Pipe Heat Sinks do not generate any noise as they do not require noisy fans or pumps to operate.

4. Materials Used in Heat Pipe Heat Sinks

Heat Pipe Heat Sinks can be made from several materials, including aluminum, copper, and graphite. Aluminum is the most commonly used material due to its excellent thermal conductivity, low cost, and light weight. Copper is a superior thermal conductor but is more expensive and heavier than aluminum. Graphite is an emerging material in this field and has the potential to offer better thermal performance than both aluminum and copper.

5. Applications of Heat Pipe Heat Sinks

Heat Pipe Heat Sinks find applications in various fields, mainly in electronics. They are used in:

- Computers and laptops

- Servers, routers, and switches

- Telecommunications equipment

- LED lighting

- Solar panels

- Industrial equipment

- Medical devices

- Aerospace industry

6. Factors to Consider when Selecting Heat Pipe Heat Sinks

When selecting a Heat Pipe Heat Sink for your application, several factors should be taken into consideration:

- The thermal requirements of the component: Ensure that the heat sink can handle the heat generated by the component.

- The size and weight of the heat sink: Make sure that the heat sink is not too big or too heavy for your application.

- The installation process: Choose a heat sink that is easy to install and fits your application's mounting requirements.

- The cost: Compare the cost of different heat sinks and choose the one that offers the best value for your money.

7. Installation and Maintenance of Heat Pipe Heat Sinks

Heat Pipe Heat Sinks are easy to install and require minimal maintenance. To install a Heat Pipe Heat Sink, follow these steps:

- Clean the surface of the component to remove any dirt or debris.

- Apply a thin layer of thermal paste to the component's surface.

- Attach the Heat Pipe Heat Sink to the component and ensure that it is securely mounted.

To maintain a Heat Pipe Heat Sink:

- Clean the fins of the heat sink periodically to remove any dust or debris that may accumulate and reduce heat transfer efficiency.

- Check the mounting of the heat sink periodically to ensure that it is still secure and has not become loose.

8. Conclusion

Heat Pipe Heat Sinks are a reliable and efficient solution for thermal management in electronic devices. They offer several advantages over traditional heat sinks, including higher thermal conductivity, uniform temperature distribution, no moving parts, and no noise. They are easy to install and require minimal maintenance, making them an ideal choice for a variety of applications.

9. Related Long-Tail SEO Keywords

- Heat Pipe Heat Sink for LED lighting

- Heat Pipe Heat Sink for solar panels

- Heat Pipe Heat Sink for medical devices

- Benefits of Heat Pipe Heat Sinks

- How to select a Heat Pipe Heat Sink

- Installation of Heat Pipe Heat Sinks

- Maintenance of Heat Pipe Heat Sinks

- Heat Pipe Heat Sink versus traditional heat sinks

- Cost-effective Heat Pipe Heat Sinks

10. Key Takeaways

- Heat Pipe Heat Sinks are passive devices that use a combination of evaporation and condensation to transfer heat away from electronic components.

- They offer several advantages over traditional heat sinks, including higher thermal conductivity, uniform temperature distribution, no moving parts, and no noise.

- Heat Pipe Heat Sinks are easy to install and require minimal maintenance, making them an ideal choice for various applications.

- When selecting a Heat Pipe Heat Sink, consider the thermal requirements of the component, the size and weight of the heat sink, the installation process, and the cost.