The Importance of Thermal Management

Thermal management is a crucial aspect of modern electronics. With the increasing power density and heat generation in electronics devices, efficient cooling solutions are essential to ensure optimal performance and longevity.

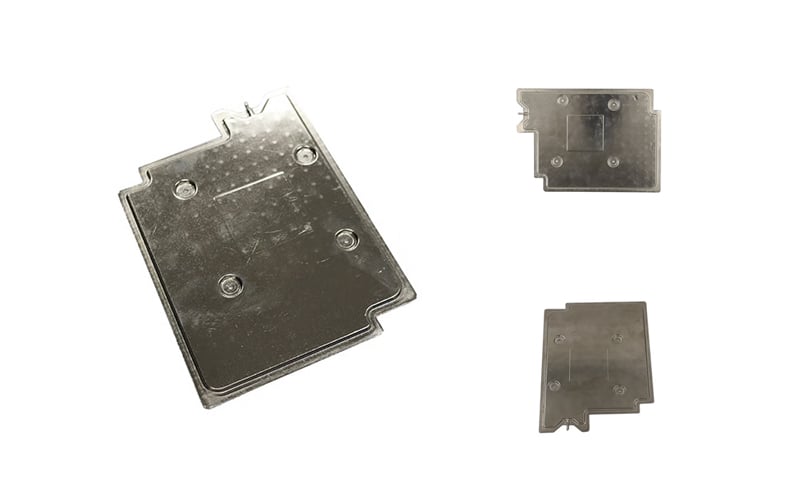

Introduction to Copper Vapor Chambers

Copper vapor chambers are advanced thermal management solutions that are becoming increasingly popular due to their high thermal conductivity and excellent heat spreading capabilities. They are used in various electronic devices, including laptops, smartphones, and servers.

Manufacturing Process of Copper Vapor Chambers

The manufacturing process of copper vapor chambers involves several steps. It starts with the deposition of copper onto a substrate, followed by the formation of a vacuum-sealed chamber. The copper is then vaporized inside the chamber, creating a highly efficient heat transfer mechanism.

Advantages of Copper Vapor Chambers

Copper vapor chambers offer several advantages over traditional cooling solutions. They provide uniform heat distribution, reduced hot spots, and improved thermal performance. Additionally, they are thin and lightweight, making them ideal for compact electronic devices.

Applications of Copper Vapor Chambers

Copper vapor chambers are used in a wide range of electronic devices, including gaming consoles, LED lighting systems, and automotive electronics. Their versatility and efficiency make them an ideal choice for high-performance applications that require effective thermal management.

Benefits of Using Copper Vapor Chambers

Using copper vapor chambers in electronic devices can lead to enhanced reliability and performance. They help prevent overheating and thermal throttling, ensuring that the device operates at optimal temperatures even under heavy workloads.

Quality Control in copper vapor chamber manufacturing

Ensuring the quality of copper vapor chambers is essential to their performance and longevity. Manufacturers use advanced testing methods, such as thermal imaging and pressure testing, to guarantee that each chamber meets the required specifications and standards.

Future Trends in Copper Vapor Chamber Technology

As electronic devices continue to evolve and become more powerful, the demand for efficient thermal management solutions like copper vapor chambers will only increase. Manufacturers are constantly innovating to improve their performance and make them more cost-effective.

Environmental Impact of Copper Vapor Chamber Manufacturing

While copper vapor chambers offer significant benefits in terms of thermal management, their manufacturing process can have environmental implications. Manufacturers are exploring sustainable practices and materials to reduce the environmental footprint of producing these advanced cooling solutions.

Conclusion

In conclusion, copper vapor chambers are revolutionizing the way electronic devices are cooled. Their high thermal conductivity, excellent heat spreading capabilities, and versatility make them an ideal choice for various applications. As the demand for efficient thermal management solutions continues to grow, copper vapor chamber manufacturing will play a crucial role in shaping the future of electronics.