What are Skived Heat Sinks?

Skived heat sinks are a type of heat sink used in electronic devices to dissipate heat and ensure optimal performance. They are made by cutting thin layers of metal, usually aluminum or copper, from a solid block. This creates a large surface area for heat transfer, making skived heat sinks highly efficient at cooling electronic components.

The Prototyping Process

Prototyping with skived heat sinks involves creating a sample or model of the final product to test its design and functionality. During the prototyping process, engineers can experiment with different sizes, shapes, and materials of skived heat sinks to find the optimal solution for their specific application.

Benefits of Skived Heat Sinks

Skived heat sinks offer several advantages, including improved thermal performance, reduced size and weight, and increased reliability. They are also cost-effective and can be customized to meet the specific requirements of a project.

Types of Skived Heat Sinks

There are various types of skived heat sinks available, including straight fin, pin fin, and elliptical fin designs. Each type has its own unique characteristics and cooling capabilities, allowing engineers to choose the best option for their application.

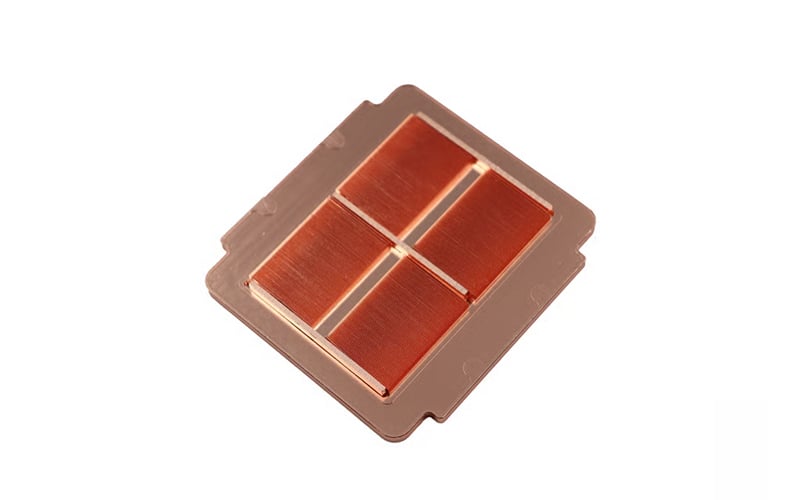

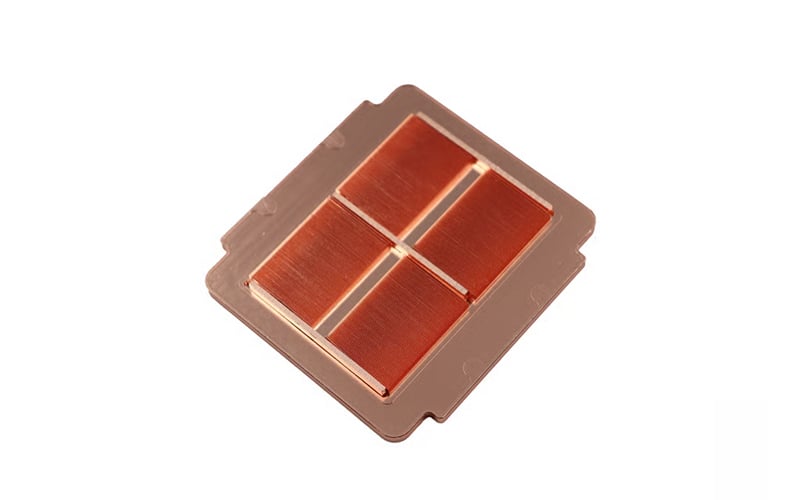

Materials Used in Skived Heat Sinks

Skived heat sinks are typically made from aluminum or copper, as these materials have high thermal conductivity and are lightweight. Aluminum is a popular choice for its affordability and corrosion resistance, while copper is preferred for its superior thermal conductivity.

Prototyping Methods

There are different methods of prototyping with skived heat sinks, such as CNC machining, laser cutting, and 3D printing. Each method has its own advantages and limitations, so engineers must choose the most appropriate technique based on their project requirements.

Design Considerations

When prototyping with skived heat sinks, engineers must consider factors such as thermal resistance, surface finish, and airflow to ensure optimal cooling performance. The design of the heat sink plays a crucial role in its effectiveness in dissipating heat from electronic components.

Testing and Evaluation

Once the prototype with skived heat sinks is built, it undergoes testing and evaluation to assess its thermal performance and reliability. Engineers use advanced tools and software to analyze the heat dissipation capabilities of the heat sink and make any necessary adjustments.

Applications of Skived Heat Sinks

Skived heat sinks are widely used in various industries, including telecommunications, aerospace, automotive, and consumer electronics. They are essential for cooling electronic components such as CPUs, GPUs, power amplifiers, and LED lighting systems.

Future Trends in Skived Heat Sinks

As technology continues to advance, the demand for more efficient and compact cooling solutions will drive the development of innovative skived heat sinks. Future trends may include the use of new materials, advanced manufacturing processes, and integrated thermal management solutions.

Quote Inquiry

contact us