The Importance of Fin Density Optimization

Achieving optimal fin density in skiving is crucial for improving heat dissipation efficiency in various applications, such as electronics cooling systems and heat exchangers. This article will delve into the key aspects of fin density optimization and its impact on overall thermal performance.

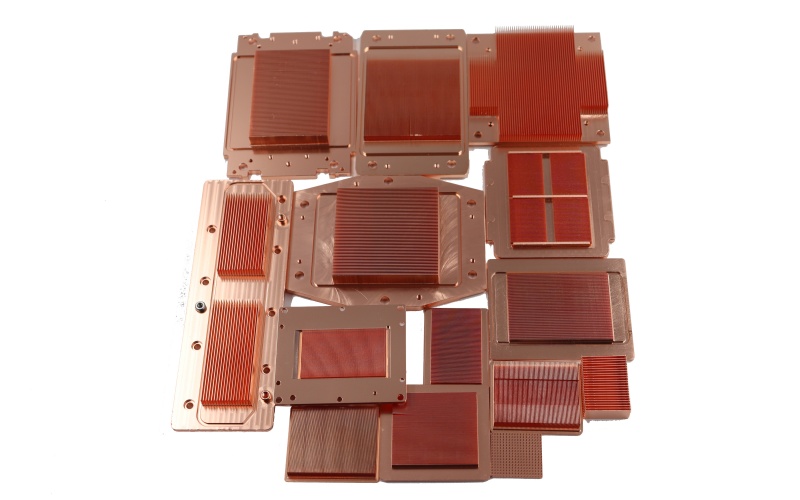

Understanding Skiving Process

Skiving is a machining process used to create fins on heat sinks, heat exchangers, and other thermal management devices. By removing material from a metal block in a controlled manner, the skiving process facilitates the formation of closely spaced fins that enhance heat transfer from the device.

Benefits of Higher Fin Density

Increasing fin density in skiving results in a larger surface area for heat dissipation, improving the overall thermal efficiency of the cooling system. Higher fin density also allows for better heat transfer between the fins and the air or liquid medium, leading to more effective cooling performance.

Challenges of High Fin Density

While higher fin density offers significant benefits, it also presents challenges in terms of manufacturing complexity and cost. Achieving and maintaining uniform fin density across a large surface area can be challenging, requiring precise control and advanced machining techniques.

Optimization Techniques

Several techniques can be employed to optimize fin density in skiving, including adjusting cutting parameters, optimizing tool design, and utilizing advanced machining technologies. By fine-tuning these factors, manufacturers can achieve the desired fin density while maintaining cost-effectiveness.

Material Considerations

The choice of material plays a crucial role in Fin density optimization in skiving. Different materials have varying thermal conductivity properties, which can affect the heat dissipation efficiency of the cooling system. Selecting the right material is essential for maximizing thermal performance.

Thermal Performance Testing

Thermal performance testing is essential for evaluating the effectiveness of fin density optimization in skiving. By conducting rigorous testing and analysis, manufacturers can identify areas for improvement and fine-tune the fin density to achieve optimal heat dissipation efficiency.

Market Trends and Innovations

The demand for high-performance thermal management solutions has led to continuous advancements in fin density optimization technologies. Innovations in skiving processes, materials, and design techniques are driving the development of more efficient cooling systems across various industries.

Future Prospects

As technology continues to evolve, the need for efficient thermal management solutions will only grow. Fin density optimization in skiving is expected to play a crucial role in meeting the increasing demands for high-performance cooling systems in a wide range of applications.

Conclusion

In conclusion, optimizing fin density in skiving is essential for achieving enhanced thermal performance in cooling systems. By understanding the importance of fin density, employing effective optimization techniques, and staying abreast of market trends and innovations, manufacturers can develop cutting-edge cooling solutions that meet the demands of the modern industry.