Methods of Heat Sink Cooling: A Comprehensive Guide

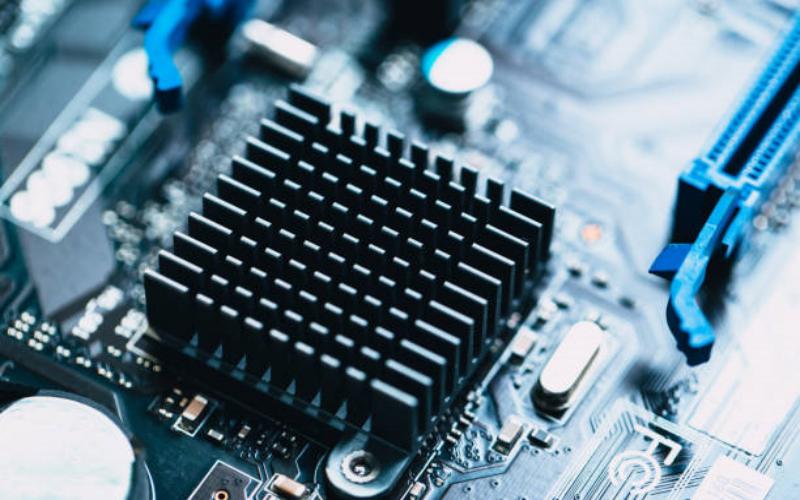

Heat sink cooling is a vital aspect of electronic devices and systems, ensuring their optimal performance and longevity. Heat sinks are passive cooling solutions that dissipate heat generated by electronic components, such as processors, transistors, and power modules. In this article, we will explore various methods of heat sink cooling, their advantages, and their applications.

Air Cooling

Air cooling is one of the most common and cost-effective methods of heat sink cooling. It relies on the principle of convection to transfer heat away from the heat sink. Air cooling involves the use of fans or natural airflow to enhance heat dissipation. The heat sink is designed with fins, which increase the surface area for better heat transfer. Air cooling is widely used in desktop computers, servers, and other electronic devices.

Liquid Cooling

Liquid cooling, also known as water cooling, is a more efficient method of heat sink cooling compared to air cooling. It involves circulating a liquid coolant, such as water or a specialized coolant, through the heat sink to absorb and carry away heat. Liquid cooling systems can achieve higher cooling capacities and lower temperatures, making them ideal for high-performance gaming PCs, overclocked processors, and server farms.

Heat Pipes

Heat pipes are another effective method of heat sink cooling. A heat pipe is a sealed tube filled with a working fluid, typically a low boiling point liquid such as water or ammonia. When the heat source (e.g., a processor) heats up, the working fluid evaporates, carrying heat to the cool end of the pipe. At the cool end, the vapor condenses and releases the heat. Heat pipes offer excellent heat transfer capabilities and are often used in laptops, graphics cards, and LED lighting systems.

Thermoelectric Cooling

Thermoelectric cooling, also known as Peltier cooling, is a unique method that utilizes the Peltier effect to transfer heat. It involves the use of thermoelectric modules that consist of two dissimilar semiconductor materials. When an electrical current is applied, one side of the module absorbs heat while the other side dissipates it. Thermoelectric cooling is commonly used in niche applications where precise temperature control is required, such as medical equipment and scientific instruments.

Vapor Chamber Cooling

Vapor chamber cooling is a more advanced and efficient method of heat sink cooling. It utilizes the principles of heat pipes but on a larger scale. A vapor chamber is a flat, sealed container filled with a small amount of working fluid. When heat is applied, the fluid vaporizes, spreading the heat evenly across the chamber. The vapor then condenses and releases the heat at the cooling end. Vapor chamber cooling is found in high-performance gaming laptops, graphics cards, and high-end CPUs.

Phase-Change Materials

Phase-change materials (PCMs) are substances that undergo a phase transition, such as from solid to liquid or liquid to gas, absorbing or releasing a significant amount of heat in the process. PCMs are used in heat sinks to enhance heat transfer and cooling efficiency. When the temperature rises, the PCM absorbs heat and changes phase, effectively drawing heat away from the electronic component. PCMs are commonly found in various electronic devices, including smartphones, tablets, and automotive electronics.

Forced Convection

Forced convection is a method of heat sink cooling that utilizes a forced flow of air or liquid to enhance heat transfer. It involves the use of fans or pumps to create a continuous flow of air or liquid across the heat sink, increasing the rate of heat dissipation. Forced convection is commonly used in server racks, industrial machinery, and high-performance electronic systems where passive cooling methods are insufficient.

Natural Convection

Natural convection is a passive cooling method that relies on the natural movement of air due to density differences caused by temperature gradients. Heat sinks designed for natural convection have larger fins to maximize surface area and promote airflow. Natural convection is commonly used in low-power electronic devices, household appliances, and automotive electronics.

Heat Sink Materials

The choice of heat sink material is crucial for effective heat dissipation. Aluminum and copper are the most commonly used materials due to their excellent thermal conductivity. Aluminum is lightweight and cost-effective, making it suitable for most applications. Copper, on the other hand, has superior thermal conductivity but is heavier and more expensive. Other materials, such as graphite and ceramic composites, are also used for specialized applications.

Thermal Interface Materials

Thermal interface materials (TIMs) play a vital role in heat sink cooling by filling the microscopic gaps between the heat sink and the electronic component. TIMs enhance heat transfer by reducing thermal resistance and ensuring optimal contact between the two surfaces. Common TIMs include thermal greases, thermal pads, and thermal adhesives. The choice of TIM depends on factors such as thermal conductivity, ease of application, and electrical insulation properties.