Introduction

Liquid heat sinks are an essential component of modern cooling systems, used in various industries to dissipate heat efficiently. The selection of the right liquid for liquid heat sinks is crucial to ensure optimal performance and prevent any potential issues. In this article, we will explore the importance of Liquid selection for liquid heat sinks and discuss various factors to consider when choosing the appropriate coolant.

Thermal Conductivity: The Key Factor

When it comes to liquid selection for liquid heat sinks, thermal conductivity is the most critical factor. Thermal conductivity refers to the ability of a material to conduct heat. The higher the thermal conductivity of the liquid, the more effectively it can transfer heat away from the heat source. Therefore, it is essential to choose a coolant with high thermal conductivity to maximize the efficiency of the liquid heat sink.

Viscosity of Liquid Heat Sink: Balancing Flow and Resistance

Viscosity is another crucial aspect to consider when selecting a liquid for liquid heat sinks. Viscosity refers to the thickness or resistance to flow of a liquid. While a high-viscosity coolant may provide better heat transfer, it can also increase the flow resistance, leading to reduced efficiency and increased pumping requirements. Conversely, a low-viscosity liquid may have excellent flow characteristics but might compromise heat transfer. Striking the right balance between viscosity and flow is vital to ensure optimal performance.

Chemical Compatibility: Avoiding Corrosion and Contamination

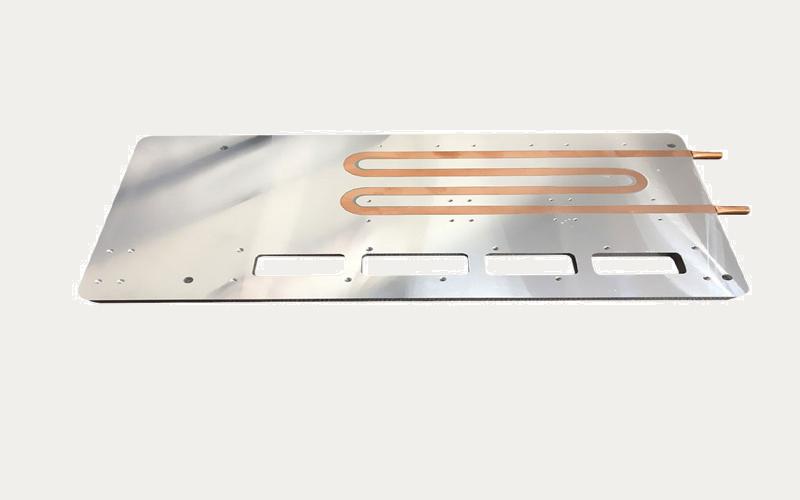

Chemical compatibility is a critical consideration when choosing a liquid for liquid heat sinks. The coolant should be compatible with the materials used in the heat sink, such as copper, aluminum, or other metals. Incompatible liquids can lead to corrosion, which not only compromises the heat sink's lifespan but also introduces contaminants that can obstruct flow passages. It is crucial to select a coolant that is chemically compatible with the heat sink materials to avoid these issues.

Boiling Point: Preventing Cavitation and Vapor Lock

Boiling point is another factor to consider when selecting a liquid for liquid heat sinks. The boiling point of the coolant should be significantly higher than the operating temperature of the heat sink to prevent cavitation and vapor lock. Cavitation occurs when the coolant boils and forms bubbles, reducing the heat transfer efficiency. Vapor lock, on the other hand, happens when vapor bubbles obstruct the flow, resulting in a loss of cooling capacity. Choosing a liquid with an appropriate boiling point is crucial to prevent these issues.

Specific Heat Capacity: Maximizing Heat Absorption

Specific heat capacity is a measure of the amount of heat energy a substance can absorb. A coolant with a high specific heat capacity can absorb more heat before reaching its temperature limit, providing a greater cooling capacity. Therefore, selecting a liquid with a high specific heat capacity is essential to maximize the heat absorption capability of the liquid heat sink.

Thermal Stability of Liquid Heat Sink: Ensuring Longevity

Thermal stability of the liquid is an important consideration to ensure the longevity of the liquid heat sink. The coolant should be able to withstand high operating temperatures without decomposing or degrading over time. A thermally stable liquid will maintain its performance and properties, preventing any issues that may arise from thermal degradation.

Environmental Impact: Considering Eco-Friendly Options

In today's environmentally conscious world, considering the environmental impact of the coolant is crucial. Some liquids used in liquid heat sinks may have adverse effects on the environment, such as high global warming potential or ozone depletion potential. Choosing eco-friendly alternatives can help reduce the environmental footprint of cooling systems while maintaining optimal performance.

Contaminant Resistance of Liquid Heat Sink: Protecting Against Impurities

Contaminants can have a detrimental effect on the performance of liquid heat sinks. Therefore, selecting a coolant that is resistant to contaminants is essential. The liquid should be able to resist fouling, scaling, and other impurities that can accumulate over time and reduce the heat transfer efficiency. Choosing a contaminant-resistant liquid can help maintain the long-term performance of the liquid heat sink.

Cost Considerations: Balancing Performance and Budget

While performance is crucial, cost considerations cannot be ignored. Some high-performance coolants may come at a premium price, which may not be justifiable for certain applications. It is important to strike a balance between the desired performance and the budget constraints when selecting a liquid for liquid heat sinks. Conducting a cost-benefit analysis can help determine the most cost-effective solution without compromising performance.