Introduction

The demand for high-performance electronics has never been greater. As devices get smaller and more power-hungry, the problem of heat dissipation becomes increasingly challenging. One effective solution is the

liquid cold plate heat sink. In this article, we will explore the benefits and applications of this technology.

What is a Liquid Cold Plate Heat Sink?

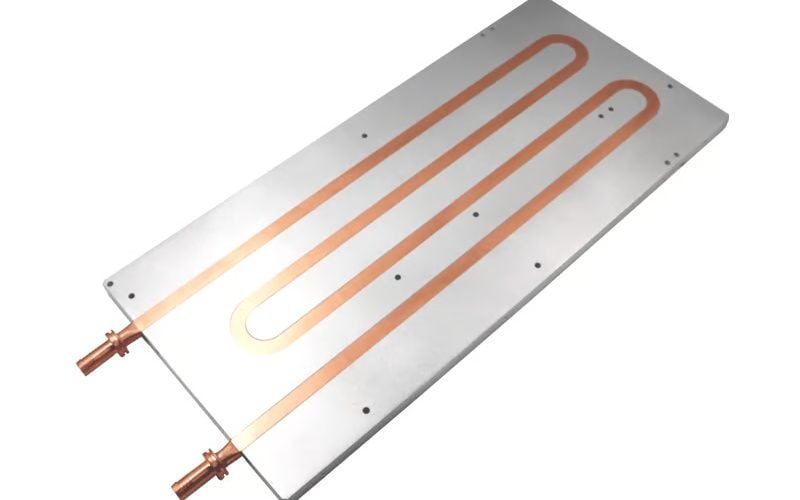

A liquid cold plate heat sink is a device that transfers heat from a heat source to a liquid coolant, which then carries the heat away from the source. The coolant flows through a series of channels or tubes in the cold plate, which are in direct contact with the heat source. As the coolant absorbs the heat, it evaporates and transfers the heat away through a heat exchanger.

Benefits of Liquid Cold Plate Heat Sinks

One of the primary benefits of liquid cold plate heat sinks is their efficiency. Unlike traditional air-cooled heat sinks, liquid cold plates can handle much higher heat loads and maintain a more uniform temperature across the heat source. This can result in improved performance, increased reliability, and longer lifespan for electronic devices.

Applications of Liquid Cold Plate Heat Sinks

Liquid cold plate heat sinks are used in a wide range of applications, including:

- Electronic cooling

- Power electronics

- Laser diodes

- LEDs and lighting

- Medical equipment

- Military and aerospace

Design Considerations

When designing a liquid cold plate heat sink, there are several factors to consider. These include the heat load, coolant flow rate, material selection, and thermal resistance. Additionally, it is important to ensure that the cold plate is compatible with the heat source, such as through proper mounting and thermal interface materials.

Types of Liquid Cold Plate Heat Sinks

There are several types of liquid cold plate heat sinks available, including:

- Single-phase liquid cold plates, which use a single liquid coolant

- Two-phase liquid cold plates, which use a boiling liquid coolant

- Direct-to-chip cold plates, which are designed for direct contact with the heat source

- Manifold cold plates, which distribute coolant to multiple heat sources

Materials for Liquid Cold Plate Heat Sinks

The choice of material for a liquid cold plate heat sink depends on several factors, including thermal conductivity, corrosion resistance, and cost. Common materials include copper, aluminum, and stainless steel. In some applications, exotic materials such as diamond, graphite, or ceramics may be used.

Advancements in Liquid Cold Plate Heat Sinks

Recent years have seen significant advancements in liquid cold plate heat sink technology. These include microchannel designs, which can improve thermal performance and reduce coolant requirements, and additive manufacturing techniques such as 3D printing, which allow for complex geometries and customization.

Conclusion

Liquid cold plate heat sinks provide an efficient and effective solution for electronics cooling. Whether it's for a high-powered server, a medical device, or a military application, a liquid cold plate heat sink can help ensure that electronic devices perform at their best.

Quote Inquiry

Contact us!