The Basics of IGBT Liquid Cooling

IGBT (Insulated Gate Bipolar Transistor) liquid cooling is a crucial aspect of many industrial applications, especially those involving high power electronic systems. This innovative cooling method helps to maintain optimal temperature levels and improve the overall performance and reliability of IGBT modules. In this article, we will delve into the world of IGBT liquid cooling, exploring its benefits, working principles, and various techniques used. Whether you are an engineer, technician, or simply curious about the topic, this comprehensive guide will provide you with all the essential information you need to know.

Understanding IGBT Modules

Before delving into the specifics of IGBT liquid cooling, it is important to have a clear understanding of IGBT modules themselves. IGBTs are power electronic devices that combine the best qualities of both bipolar junction transistors (BJTs) and metal-oxide-semiconductor field-effect transistors (MOSFETs). These modules are widely used in applications such as motor drives, renewable energy systems, electric vehicles, and welding equipment, to name a few. IGBTs play a crucial role in controlling and converting electrical power efficiently, making them an integral part of modern industrial systems.

The Importance of Cooling IGBT Modules

IGBT modules generate a significant amount of heat during operation due to the high power levels involved. This heat, if not properly dissipated, can lead to reduced performance, increased failure rates, and even permanent damage to the components. Cooling IGBT modules is essential to maintain their temperature within safe operating limits, ensuring optimal performance and longevity. While various cooling methods exist, liquid cooling has emerged as one of the most effective and efficient techniques for IGBT modules.

How Does IGBT Liquid Cooling Work?

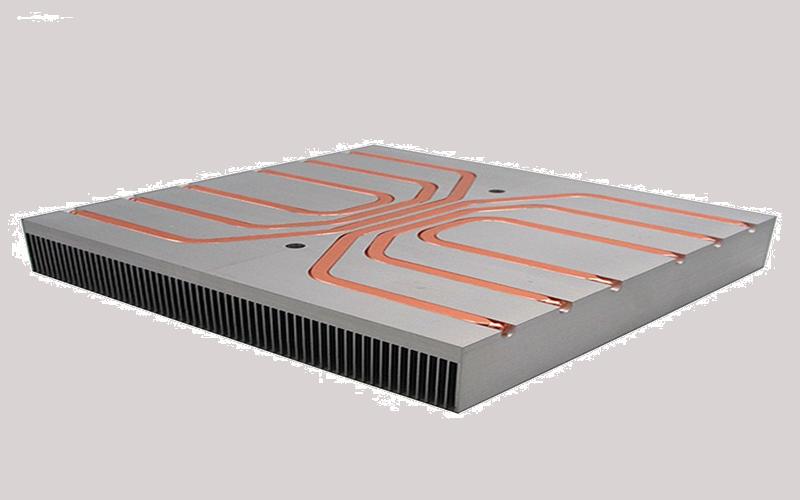

IGBT liquid cooling involves the use of a liquid, typically water-based, to remove heat from the IGBT modules. The liquid absorbs the heat generated by the modules and carries it away, preventing the temperature from rising to dangerous levels. This cooling process is facilitated by the presence of a heat sink or cold plate, which is in direct contact with the IGBT module. The liquid flows through the heat sink, absorbing heat and dissipating it through various means, such as natural convection or forced convection using fans or pumps.

The Benefits of IGBT Liquid Cooling

IGBT liquid cooling offers several advantages over traditional cooling methods, such as air cooling. Firstly, liquid cooling provides better thermal conductivity, allowing for more efficient heat dissipation. This results in lower junction temperatures and improved overall reliability of the IGBT modules. Additionally, liquid cooling enables more compact designs, as it eliminates the need for bulky heat sinks typically associated with air cooling. Furthermore, liquid cooling reduces noise levels, as fans or blowers used for air cooling can be eliminated or run at lower speeds, resulting in quieter operation.

Techniques Used in IGBT Liquid Cooling

There are several techniques employed in IGBT liquid cooling systems, each with its own strengths and applications. One common method is direct liquid cooling, where the liquid flows directly through the IGBT module, maximizing heat transfer efficiency. Indirect liquid cooling, on the other hand, involves cooling the module indirectly through a heat sink or cold plate. Another technique is immersion cooling, where the entire IGBT module is submerged in a dielectric liquid. This method provides excellent cooling performance but requires additional safety measures due to the presence of liquid.

Considerations for IGBT Liquid Cooling Systems

When designing or implementing an IGBT liquid cooling system, several factors must be taken into consideration. These include the choice of coolant, flow rate, pressure drop, compatibility with materials, and system maintenance requirements. It is crucial to select a coolant that offers high thermal conductivity and good chemical stability. The flow rate should be optimized to ensure efficient heat transfer, while the pressure drop must be minimized to avoid unnecessary energy losses. Additionally, compatibility with materials such as seals, gaskets, and tubing is essential to prevent leaks or corrosion.

Challenges and Solutions in IGBT Liquid Cooling

Although IGBT liquid cooling offers numerous benefits, it also presents certain challenges. One common challenge is the potential for leakage or system failure due to the presence of liquid. This can be mitigated through the use of reliable seals and proper system design. Another challenge is the maintenance of cleanliness within the cooling system to prevent clogging or fouling. Regular system inspections, filtration, and appropriate maintenance protocols can help overcome this challenge. Additionally, it is essential to consider the overall system cost and complexity when implementing IGBT liquid cooling solutions.

Advancements in IGBT Liquid Cooling

As technology continues to evolve, so does the field of IGBT liquid cooling. Researchers and engineers are constantly exploring new techniques and materials to improve the cooling efficiency and reliability of IGBT modules. Advancements such as microchannel coolers, phase-change materials, and advanced control algorithms are being developed to further enhance the performance of IGBT liquid cooling systems. These advancements promise to unlock even greater potential for IGBT modules, enabling them to operate at higher power levels and in more demanding applications.

The Future of IGBT Liquid Cooling

The future of IGBT liquid cooling looks promising, with ongoing research and development aimed at addressing the challenges and limitations of current cooling methods. As industrial systems continue to demand higher power densities and improved reliability, the role of IGBT liquid cooling will become even more critical. With advancements in materials, design, and control, we can expect more efficient and compact cooling solutions, enabling the widespread adoption of IGBT modules in a wide range of applications.