Understanding Heat Pipes

Heat pipes are passive heat transfer devices that are used to efficiently transfer heat between two solid interfaces. They are commonly used in various industries such as electronics, aerospace, and HVAC systems to manage thermal loads effectively.

Key Considerations in Heat Pipe Selection

When selecting the right heat pipe for your project, there are several key factors to consider. These include operating temperature range, thermal conductivity, working fluid, wick structure, and heat pipe geometry.

Operating Temperature Range

One of the most critical factors in selecting a heat pipe is its operating temperature range. Different heat pipes are designed to operate within specific temperature ranges, so it is essential to choose one that is suitable for your project's requirements.

Thermal Conductivity

The thermal conductivity of a heat pipe determines its ability to transfer heat efficiently. Higher thermal conductivity values indicate better heat transfer capabilities, so it is crucial to consider this factor when selecting a heat pipe for your project.

Working Fluid

The working fluid inside a heat pipe plays a significant role in its thermal performance. Different working fluids have varying thermal conductivities and operating temperature ranges, so it is essential to choose the right fluid based on your project's requirements.

Wick Structure

The wick structure of a heat pipe influences its ability to transport the working fluid and manage heat transfer. The wick can be made of materials such as sintered metal, grooved metal, or mesh, with each type offering different thermal performance characteristics.

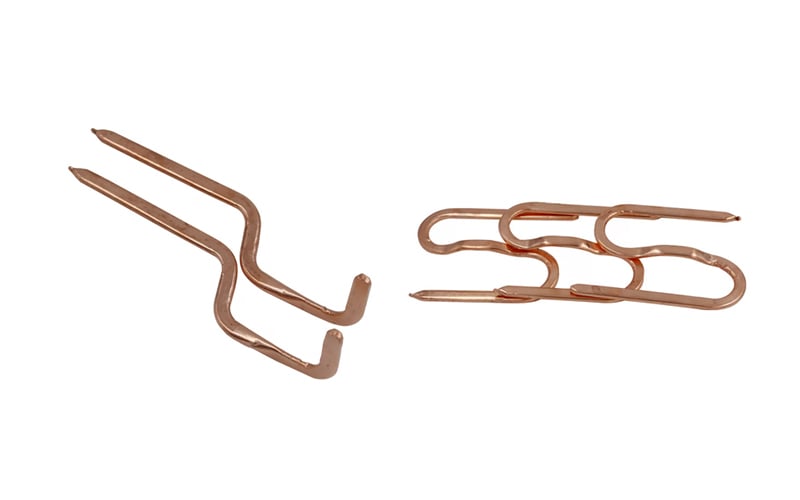

Heat Pipe Geometry

The geometry of a heat pipe, including its length, diameter, and shape, can impact its thermal performance and heat transfer capabilities. It is essential to consider the specific requirements of your project when selecting the right heat pipe geometry.

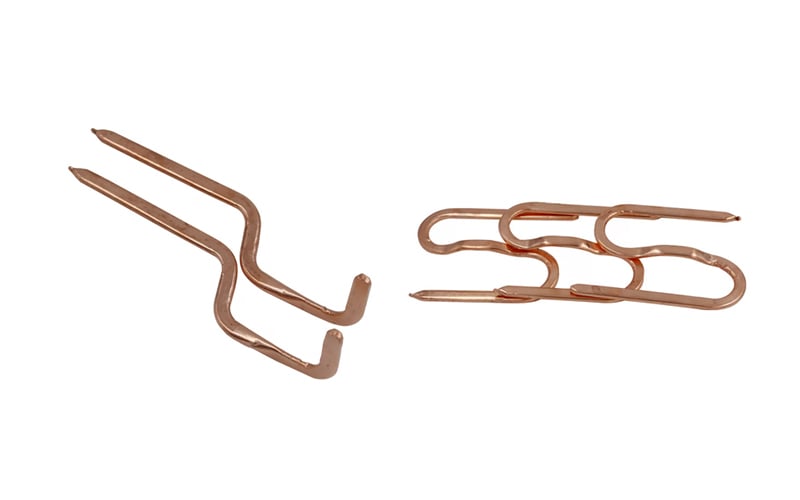

Customizable Options

Many heat pipe manufacturers offer customizable options to meet the unique needs of different projects. This includes custom lengths, diameters, wick structures, and working fluids, allowing you to tailor the heat pipe to your specific requirements.

Testing and Validation

Before finalizing your heat pipe selection, it is crucial to conduct testing and validation to ensure that the chosen heat pipe meets your project's performance requirements. This may involve thermal testing, pressure testing, and other validation procedures.

Supplier Reputation and Support

When selecting a heat pipe for your project, it is essential to consider the reputation and support of the supplier. Choosing a reliable and experienced supplier can help ensure the quality of the heat pipe and provide valuable technical support throughout the project.

Quote Inquiry

Contact us