The Ultimate Guide on How to Make an Aluminum Thermal Heat Sink

Aluminum thermal heat sinks play a crucial role in cooling electronic devices and preventing them from overheating. Whether you are a hobbyist or a professional, knowing how to make an aluminum thermal heat sink can save you both time and money. In this comprehensive guide, we will walk you through the step-by-step process of creating an efficient aluminum heat sink. So, let's dive in!

1. Understanding the Importance of a Heat Sink

Before we delve into the process of making an aluminum thermal heat sink, it is essential to understand its significance. Heat sinks are used to dissipate heat generated by electronic components, such as transistors, CPUs, and power amplifiers. By efficiently cooling these devices, heat sinks prevent them from malfunctioning or even getting permanently damaged due to excessive heat.

2. Choosing the Right Aluminum Alloy

Aluminum is a popular choice for heat sinks due to its excellent thermal conductivity and lightweight nature. However, not all aluminum alloys are created equal when it comes to heat sink applications. The most commonly used alloys for heat sinks include 6061 and 6063. These alloys are cost-effective, readily available, and offer good thermal conductivity. Ensure you choose the appropriate alloy based on your specific requirements.

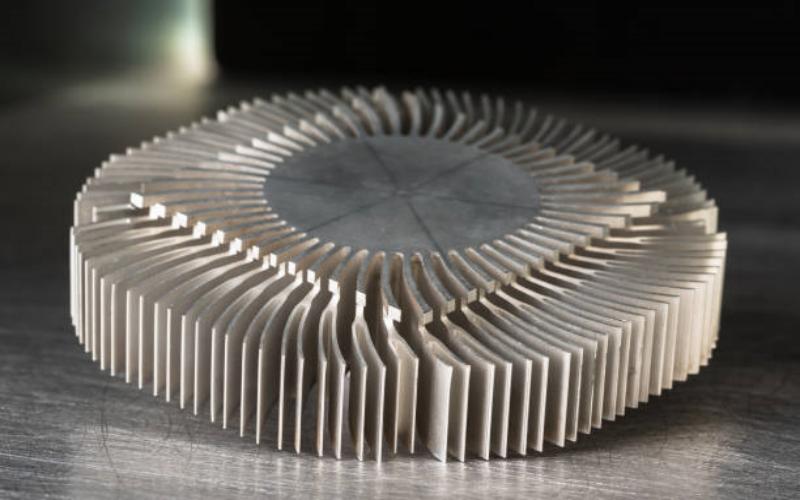

3. Designing the Heat Sink

The design of your heat sink plays a critical role in its effectiveness. To ensure optimal performance, consider factors such as the size, shape, and fin arrangement. The size of the heat sink should be proportional to the heat-generating component, allowing for efficient heat dissipation. The shape and fin arrangement should be designed to maximize surface area, which enhances heat transfer.

4. Material Preparation

Once you have finalized the design, it's time to prepare the aluminum material for fabrication. Start by cutting the aluminum sheet or extrusion to the desired dimensions using a saw or CNC machine. Ensure you wear appropriate safety gear, such as gloves and goggles, to protect yourself from any potential hazards.

5. Finishing the Surface

To enhance the heat transfer capabilities of the aluminum heat sink, it is essential to have a smooth surface. Begin by sanding the aluminum using progressively finer grits of sandpaper. Follow this up with polishing using a metal polishing compound to achieve a mirror-like finish. This smooth surface will promote better contact with the heat-generating component.

6. Creating Fins

The fins of a heat sink significantly increase its surface area, allowing for better heat dissipation. Using a CNC machine or a similar tool, carefully cut evenly spaced fins into the aluminum material. Ensure that the fins are of equal size and shape to maintain consistency throughout the heat sink.

7. Attaching the Heat Sink to the Component

Once the heat sink is fabricated, it's time to attach it to the component you wish to cool. Apply a thin layer of thermal adhesive or thermal paste to ensure proper thermal contact between the heat sink and the component. Gently press the heat sink onto the component, making sure it is firmly in place.

8. Testing and Evaluation

After the heat sink is installed, it is crucial to test its effectiveness in cooling the component. Monitor the temperature of the component using a thermal sensor or infrared thermometer. Compare the temperatures before and after installing the heat sink. If the temperature has significantly reduced, it indicates that the heat sink is functioning correctly.

9. Maintenance and Care

To ensure the longevity and optimal performance of your aluminum thermal heat sink, it is essential to maintain and care for it properly. Regularly clean the heat sink to remove any dust or debris that may accumulate on its surface. Additionally, monitor the thermal interface material between the heat sink and the component, and reapply if necessary.

10. Exploring Advanced Heat Sink Technologies

While the process described above provides a basic understanding of how to make an aluminum thermal heat sink, it is worth exploring advanced technologies in the field. These include heat pipes, vapor chambers, and active cooling solutions, which can further enhance the cooling capabilities of your heat sink.