Benefits of Using Liquid Cooling

Liquid cooling has become a popular choice for many industries due to its efficiency in dissipating heat from electronic components. Liquid coolants offer better thermal conductivity compared to air, making them a preferred option for high-performance systems.

Factors to Consider When Choosing Coolant

When selecting a coolant for liquid cold plates, it is important to consider several factors. These include thermal conductivity, corrosion resistance, viscosity, freezing point, and environmental impact. Each of these factors plays a crucial role in ensuring optimal performance and longevity of the cooling system.

Thermal Conductivity

The thermal conductivity of a coolant determines how effectively it can remove heat from the components. Coolants with higher thermal conductivity can transfer heat more efficiently, leading to better overall cooling performance. It is important to choose a coolant with a high thermal conductivity to ensure optimal system operation.

Corrosion Resistance

Corrosion can damage the internal components of a liquid cooling system, leading to reduced performance and potential system failure. It is essential to select a coolant that offers excellent corrosion resistance to protect the system from damage over time. Look for coolants specifically formulated to prevent corrosion in liquid cooling systems.

Viscosity

Viscosity refers to the thickness of the coolant and plays a critical role in the flow rate inside the cooling system. A coolant with the right viscosity ensures proper circulation and heat transfer, preventing clogs and blockages that can hinder overall performance. Choose a coolant with a viscosity that is compatible with your system's requirements.

Freezing Point

The freezing point of a coolant determines its ability to withstand low temperatures without solidifying. It is crucial to select a coolant with a freezing point that is lower than the lowest expected operating temperature of the system. This prevents the coolant from freezing and causing damage to the components.

Environmental Impact

Environmental considerations are becoming increasingly important when choosing a coolant for liquid cold plates. Opt for eco-friendly coolants that are biodegradable and non-toxic to minimize the environmental impact of your cooling system. Look for certifications such as EPA Safer Choice to ensure that the coolant meets environmental standards.

Compatibility with Materials

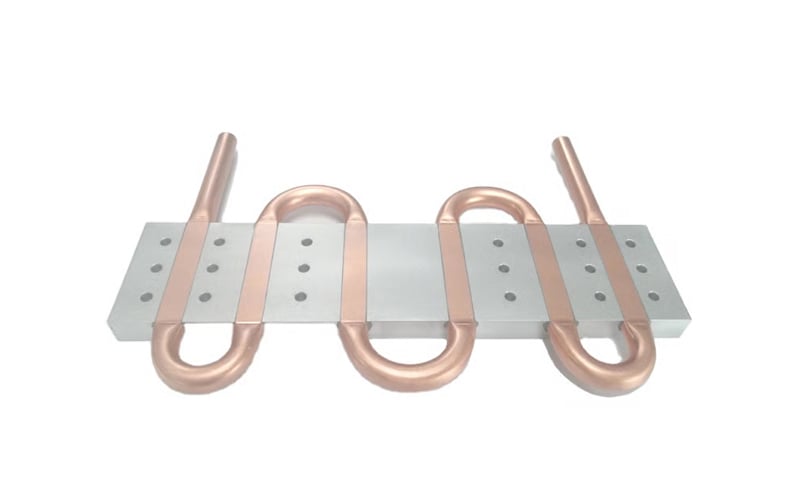

Certain coolants may not be compatible with the materials used in liquid cooling systems, leading to degradation or damage over time. It is essential to check the compatibility of the coolant with the materials present in the system, such as copper, aluminum, or nickel. Choose a coolant that is safe for use with all components in the system.

Manufacturer Recommendations

Manufacturers of liquid cold plates often provide recommendations on the type of coolant that should be used with their products. It is advisable to follow these recommendations to ensure optimal performance and compatibility with the system. Deviating from manufacturer recommendations can result in reduced cooling efficiency and potential damage to the components.

Testing and Evaluation

Before finalizing your choice of coolant for liquid cold plates, it is essential to conduct testing and evaluation to determine its suitability for the system. Perform compatibility tests, thermal performance assessments, and long-term durability evaluations to verify the effectiveness of the coolant in your specific application. This step ensures that you select the right coolant for your cooling requirements.