The Basics of a Heat Pipe

A heat pipe is a highly efficient device used to transfer heat from one location to another. It is commonly used in various industries, including electronics, aerospace, and HVAC systems. Understanding how a heat pipe is made can shed light on its remarkable properties and applications.

What are Heat Pipes Made of?

Heat pipes are typically made of a sealed copper or aluminum tube, with an inner wick structure and a working fluid. Copper is often preferred due to its excellent thermal conductivity and resistance to corrosion. The inner wick structure provides capillary action, allowing the working fluid to circulate within the pipe.

The Manufacturing Process

The manufacturing process of a heat pipe involves several steps to ensure its optimal performance:

1. Tube Formation

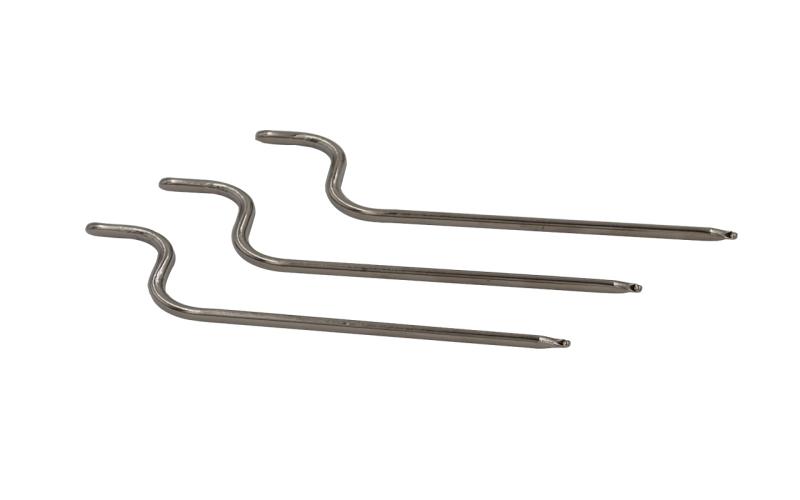

The first step is to create the outer tube, usually made of copper or aluminum. This can be done through extrusion, where the material is forced through a die to form the desired shape. Alternatively, the tube can be drawn from a larger piece of material.

2. Wick Insertion

After the tube is formed, the wick structure is inserted into the tube. The wick is typically made of sintered metal powder, such as copper or nickel, or it can be a screen mesh. The wick provides the necessary capillary action for the working fluid to flow against gravity.

3. Sealing

Once the wick is in place, the heat pipe is sealed to create a vacuum inside. This is crucial to prevent the working fluid from evaporating at low temperatures. The sealing process ensures the pipe remains hermetically sealed, allowing the heat transfer mechanism to function efficiently.

4. Evacuation and Filling

After sealing, the heat pipe undergoes evacuation to remove any remaining gases or impurities. This is done to achieve a low-pressure environment inside the pipe. Once the evacuation is complete, the working fluid is injected into the pipe through a small opening, which is then sealed.

5. Testing

Before the heat pipe is ready for use, it undergoes rigorous testing to ensure its functionality and performance. Various parameters, such as thermal conductivity, pressure drop, and heat transfer capacity, are measured to verify its efficiency.

The Working Fluid

The choice of working fluid depends on the desired operating temperature range. Commonly used working fluids include water, ammonia, acetone, and ethanol. Each fluid has specific characteristics, such as boiling point and heat transfer coefficient, which determine the heat pipe's performance.

Applications of Heat Pipes

Heat pipes find extensive use in many industries due to their exceptional heat transfer capabilities. Some common applications include:

1. Electronics Cooling

Heat pipes are widely used to cool electronic components, such as computer CPUs and graphics cards. They efficiently transfer heat away from these high-power devices, preventing overheating and ensuring optimal performance.

2. Solar Thermal Systems

Heat pipes play a crucial role in solar thermal systems by transferring heat from the solar collector to the storage tank. This improves the overall efficiency of the system and enables the utilization of solar energy for various purposes, including water heating and space heating.

3. Aerospace Industry

Heat pipes are extensively used in spacecraft and satellites to manage and distribute heat generated by electronic systems. Their lightweight and high-performance characteristics make them ideal for space applications, where weight and reliability are of utmost importance.

4. HVAC Systems

Heat pipes are used in heating, ventilation, and air conditioning (HVAC) systems to transfer heat between different areas, such as indoor and outdoor units. They enhance energy efficiency and provide more precise temperature control.

Conclusion

Heat pipes are remarkable devices that efficiently transfer heat from one location to another. Understanding the manufacturing process and applications of heat pipes can help appreciate their importance in various industries. Whether it's cooling electronic components or harnessing solar energy, heat pipes play a vital role in improving efficiency and performance.