The Basics of Heat Sinks: What Are They and How Do They Work?

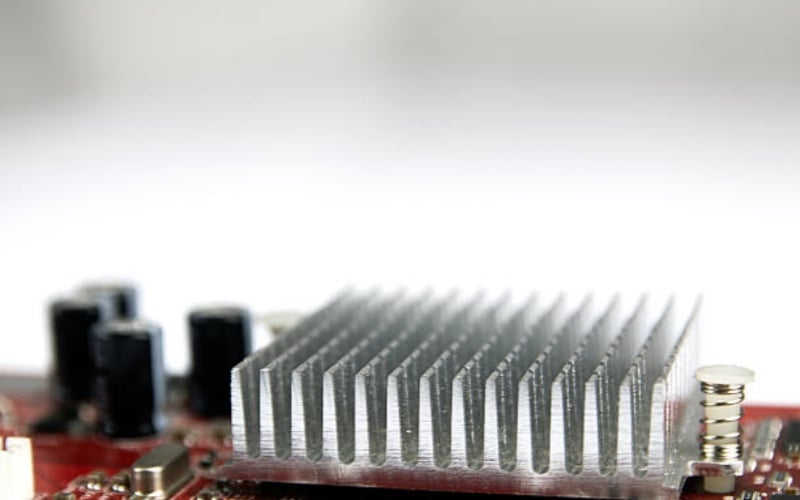

Heat sinks are a crucial component in electronic devices and systems that generate significant amounts of heat. They are designed to dissipate heat and prevent the overheating of sensitive components, ensuring the proper functioning and longevity of the device. Heat sinks work by increasing the surface area available for heat transfer and enhancing thermal conduction.

Understanding Thermal Design Power (TDP) and Its Importance

Thermal Design Power (TDP) is a measure of the maximum amount of heat a computer component, such as a central processing unit (CPU), graphics processing unit (GPU), or other integrated circuits, can generate under normal operation. It serves as a guideline for selecting an appropriate heat sink to keep the component within safe temperature limits.

Factors Affecting Heat Sink Temperature

Several factors influence how hot a heat sink can get. These include the power dissipated by the component, the thermal resistance of the heat sink, the airflow around the heat sink, and the ambient temperature. Understanding these factors is crucial for proper heat sink selection and efficient heat dissipation.

Power Dissipation: The Key Driver of Heat Sink Temperature

The power dissipated by a component is the primary factor determining the temperature of a heat sink. Components with higher power dissipation generate more heat and thus require more efficient heat sink solutions. It is essential to consider the power dissipation characteristics of the component when selecting a heat sink.

Thermal Resistance: The Role of Material and Design

Thermal resistance is a measure of how effectively a heat sink can transfer heat from the component to the surrounding environment. It depends on factors such as the material used, the design of the heat sink, and the contact between the heat sink and the component. Lower thermal resistance leads to better heat dissipation and lower heat sink temperatures.

Airflow and Heat Sink Performance

The airflow around a heat sink plays a crucial role in its performance. Adequate airflow helps remove the heat transferred from the component effectively. Factors such as fan placement, the presence of obstructions, and the heat sink's orientation affect airflow and, consequently, the heat sink's temperature. Optimizing airflow is essential for maximizing heat sink performance.

The Importance of Ambient Temperature

The ambient temperature, or the temperature of the surrounding environment, significantly impacts the heat sink's effectiveness. Higher ambient temperatures reduce the temperature gradient between the component and the surrounding air, making it more challenging for the heat sink to dissipate heat. It is crucial to consider the ambient temperature when designing or selecting a heat sink.

Thermal Interface Materials: Enhancing Heat Transfer

Thermal interface materials, such as thermal paste or thermal pads, improve heat transfer between the component and the heat sink. They fill in microscopic gaps and air pockets, ensuring better contact and reducing thermal resistance. Proper selection and application of thermal interface materials can significantly improve heat sink performance.

Pushing the Limits: Overclocking and Extreme Heat Sink Solutions

Overclocking, the practice of increasing a component's clock rate beyond its factory settings, can result in significantly higher power dissipation and temperature. To cope with extreme heat, specialized heat sink solutions, such as liquid cooling systems or high-performance heat pipes, are often employed. These solutions provide enhanced cooling capabilities and allow components to operate under extreme conditions.

The Maximum Heat Sink Temperature: A Matter of Design and Component Limitations

There is no fixed maximum temperature for a heat sink, as it depends on various factors, including the component's specifications, the heat sink's design, and the operating conditions. However, it is crucial to ensure that the heat sink's temperature remains within the safe operating limits specified by the component manufacturer to prevent performance degradation or even component failure.