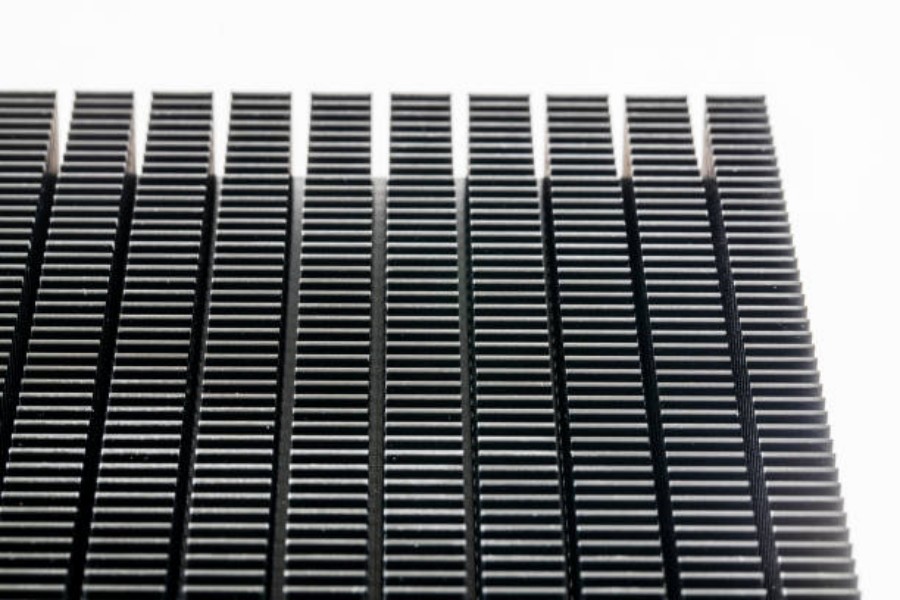

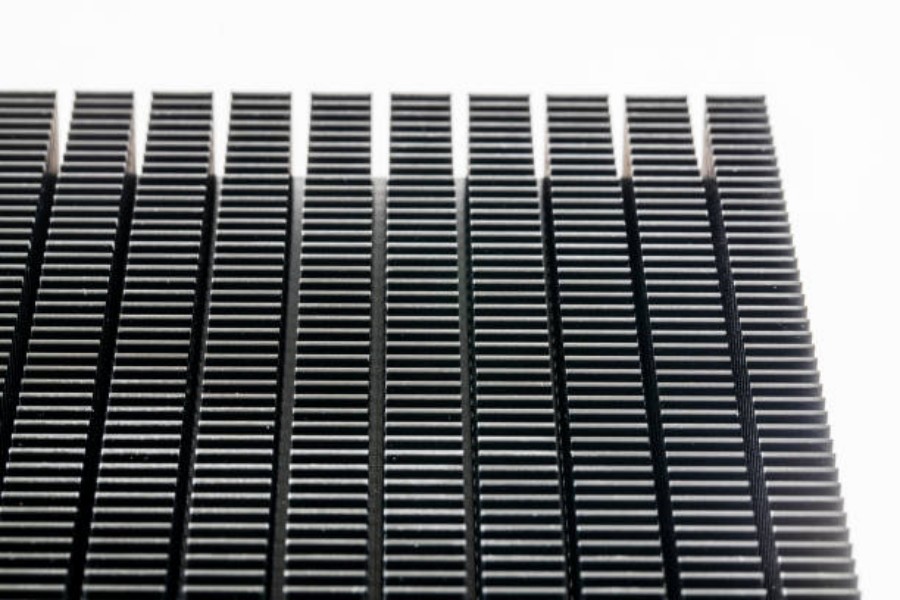

The Basics of Graphite Heat Sink

Graphite heat sink is an essential part of any heat management system. It is a high-performance material that boasts excellent thermal conductivity and superior heat dissipation capabilities. These characteristics make graphite heat sink an ideal choice for applications that require efficient heat transfer while maintaining low thermal resistance.

What is Graphite Heat Sink?

Graphite heat sink comprises a composite material that contains a mixture of graphite and a resin binder. The process of manufacturing graphite heat sink involves molding the composite into various shapes and dimensions. Graphite heat sink comes in various forms, including blocks, sheets, cones, and cylinders.

The Advantages of Graphite Heat Sink

Graphite heat sink has several advantages, including high thermal conductivity, low thermal resistance, and high-temperature durability. Additionally, graphite heat sink is lightweight, making it easy to handle and install. The material is also resistant to chemicals and harsh environments, making it suitable for various industrial applications.

Applications of Graphite Heat Sink

Graphite heat sink finds application in various industries, including electronics, aerospace, automotive, and power generation. In electronics, graphite heat sink is used to manage heat in electronic devices like smartphones, laptops, and computers. In the aerospace industry, graphite heat sink is used for heat management in aircraft components. In the automotive industry, graphite heat sink is used to cool engines, transmission, and other systems that generate high heat levels.

How to Choose Graphite Heat Sink

When selecting graphite heat sink, several factors come into play, including thermal conductivity, thermal resistance, impact resistance, and chemical resistance. The choice of graphite heat sink also depends on the application type and the heat load to be dissipated.

The Manufacturing Process of Graphite Heat Sink

The manufacturing process of graphite heat sink starts with formulating the composite. Graphite and resin binder are mixed in a specific ratio. The composite is then molded into the desired shape and dimension using pressing or extrusion techniques. The final product is then cured in an oven before undergoing further processing, including grinding and polishing.

The Properties of Graphite Heat Sink

Graphite heat sink is known for its exceptional thermal conductivity, which enables it to dissipate large amounts of heat quickly. Additionally, graphite heat sink has high-temperature durability, low thermal resistance, and excellent chemical resistance. The material is also lightweight, making it easy to handle and install.

Graphite Heat Sink vs. Other Heat Sink Materials

Graphite heat sink has several advantages over other heat sink materials. For instance, graphite heat sink has a higher thermal conductivity compared to aluminum and copper heatsinks. Additionally, graphite heat sink has excellent thermal stability compared to ceramics and other composite materials.

Maintaining Graphite Heat Sink

Graphite heat sink requires regular maintenance to ensure optimal heat dissipation. The material should be kept clean and free of dirt and debris that can clog the heat sink's channels. Additionally, the heat sink should be inspected regularly for damage or wear and tear that may affect its performance.

The Bottom Line

Overall, graphite heat sink is an essential component of any heat management system, providing excellent thermal conductivity and superior heat dissipation capabilities. The material is lightweight, durable, and easy to handle, making it an ideal choice for various applications.