Understanding the Performance of Stamped Heat Sinks

Stamped heat sinks are an essential component in many electronic systems, providing effective heat dissipation to ensure the optimal performance and longevity of electronic devices. In this article, we will explore the various aspects of stamped heat sinks performance and how they contribute to efficient thermal management.

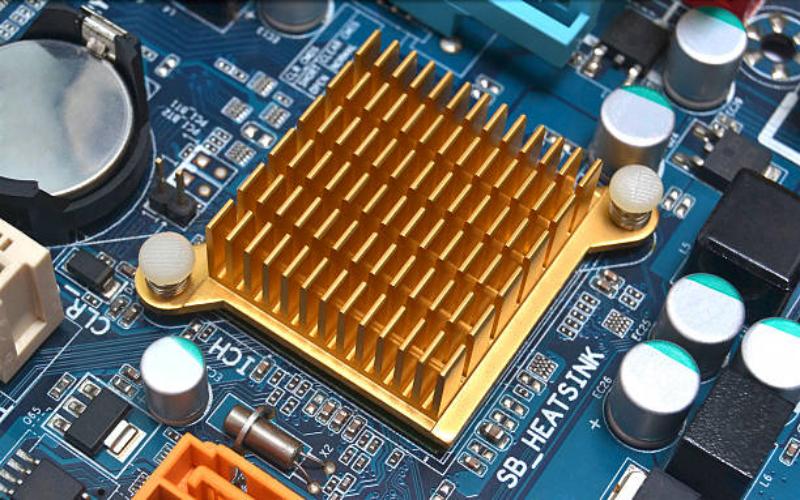

The Basics of Stamped Heat Sinks

Before diving into the details of their performance, it is important to understand what stamped heat sinks are and how they function. Stamped heat sinks are typically made from thin sheets of metal, such as aluminum or copper, that are precisely stamped or formed into a specific shape. These shapes often include fins, pins, or other protrusions to increase the surface area for better heat dissipation.

Stamped heat sinks are designed to be lightweight and cost-effective, making them suitable for a wide range of applications, including consumer electronics, telecommunications equipment, and automotive systems.

1. Thermal Conductivity

One of the key factors that determine the performance of a heat sink is its thermal conductivity. Thermal conductivity refers to the material's ability to conduct heat. In the case of stamped heat sinks, materials like aluminum and copper are commonly used due to their excellent thermal conductivity properties.

The high thermal conductivity of these metals allows heat to be efficiently transferred from the heat source (e.g., a microprocessor) to the heat sink, where it can be dissipated into the surrounding environment.

2. Surface Area and Heat Dissipation

The surface area of a heat sink plays a crucial role in its performance. Stamped heat sinks are designed with various shapes and structures to maximize the surface area available for heat dissipation. Fins, pins, and other protrusions increase the surface area, allowing for greater heat transfer to the surrounding air or a cooling medium.

By increasing the surface area, stamped heat sinks can effectively dissipate heat and prevent the electronic components from overheating, which can lead to performance degradation and even component failure.

3. Airflow and Cooling

Airflow is another important factor in the performance of stamped heat sinks. Adequate airflow helps carry away the heat absorbed by the heat sink, allowing for efficient cooling. In many applications, natural convection, where the surrounding air naturally flows over the heat sink, is sufficient.

However, in situations where natural convection is insufficient, additional cooling mechanisms like forced convection or liquid cooling may be employed. Forced convection involves using fans or blowers to enhance airflow, while liquid cooling utilizes a liquid coolant to remove heat from the heat sink.

4. Thermal Resistance

Thermal resistance is a measure of how effectively a heat sink can transfer heat. It quantifies the temperature difference between the heat source and the ambient environment for a given amount of power dissipated.

Stamped heat sinks typically have low thermal resistance due to their design and material properties. The efficient transfer of heat from the heat source to the heat sink, coupled with the increased surface area, helps minimize the temperature rise of the electronic components.

5. Manufacturing Process and Cost

The manufacturing process of stamped heat sinks contributes to their performance and cost-effectiveness. Stamping allows for high-volume production at a lower cost compared to other manufacturing methods, such as extrusion or machining.

Furthermore, the flexibility of the stamping process enables the creation of intricate heat sink designs that can be tailored to specific applications. This customization ensures optimal performance and thermal management for different electronic devices and systems.

6. Application-Specific Considerations

When selecting a stamped heat sink, it is important to consider various application-specific factors. These factors include the power dissipation requirements, available space, weight limitations, and environmental conditions.

Understanding the specific needs of the application will help in choosing the right stamped heat sink design and material to achieve optimal thermal performance.

7. Thermal Interface Materials

The performance of a stamped heat sink can also be influenced by the thermal interface materials used. Thermal interface materials, such as thermal greases or pads, are placed between the heat source and the heat sink to improve thermal conductivity and fill any microscopic air gaps.

Choosing the appropriate thermal interface material is crucial to ensure efficient heat transfer between the heat sink and the heat source, maximizing the overall thermal performance of the system.

8. Size and Weight Considerations

Stamped heat sinks offer the advantage of being lightweight and compact compared to other heat sink designs. The thin metal sheets used in their construction contribute to their low weight and small footprint, making them suitable for applications with space constraints or weight limitations.

However, it is important to ensure that the chosen stamped heat sink provides sufficient cooling capacity for the specific application, as smaller sizes may have limitations in dissipating higher heat loads.

9. Reliability and Durability

Stamped heat sinks are designed to provide long-term reliability and durability. Their robust construction and use of high-quality materials ensure that they can withstand the thermal cycling and mechanical stresses encountered in electronic systems.

By effectively dissipating heat and maintaining lower operating temperatures, stamped heat sinks contribute to the overall reliability and lifespan of the electronic components.

10. Advancements in Stamped Heat Sink Technology

As technology continues to advance, so does the design and performance of stamped heat sinks. Manufacturers are constantly innovating to improve the thermal efficiency of heat sinks, allowing for better heat dissipation in smaller form factors.

New materials, such as composite materials or alloys, are being explored to enhance thermal conductivity and reduce weight. Additionally, advanced manufacturing techniques, like additive manufacturing or microfabrication, are being employed to create intricate heat sink designs with optimized performance.

These advancements in stamped heat sink technology will continue to play a vital role in enabling the efficient cooling of electronic devices, ensuring their optimal performance in a wide range of applications.