The Importance of Stamped Heat Sinks Performance

Stamped heat sinks are an essential component in electronic devices, helping to dissipate heat and prevent overheating. In this article, we will explore the performance of stamped heat sinks and why it matters in various applications.

Understanding Stamped Heat Sinks

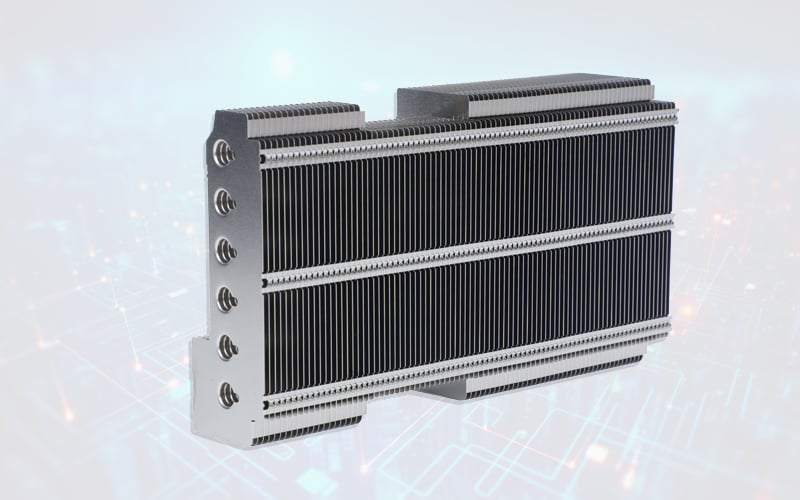

Before delving into the performance aspect, let's first understand what stamped heat sinks are. A stamped heat sink is a type of heat sink that is manufactured using a stamping process. This process involves pressing a metal sheet into a specific shape and design, resulting in a heat sink with fins or other geometric features.

Efficient Heat Dissipation

One of the primary purposes of a heat sink is to dissipate heat efficiently. Stamped heat sinks excel in this aspect due to their large surface area. The fins on a stamped heat sink increase the surface area available for heat transfer, allowing for better cooling performance.

Enhanced Airflow of Stamped Heat Sinks

Another advantage of stamped heat sinks is their ability to enhance airflow. The fins create channels through which air can flow, improving the convection process. This increased airflow helps to remove heat from the heat sink more effectively, resulting in improved overall performance.

Optimized Design for Specific Applications

Stamped heat sinks offer flexibility in design, allowing for customization based on specific application requirements. The stamping process enables the creation of intricate and tailored designs, optimizing the heat sink's performance for a particular device or system.

Lightweight and Cost-Effective

Stamped heat sinks are typically lightweight due to their design and manufacturing process. This lightweight nature makes them suitable for applications where weight is a concern. Additionally, the stamping process allows for cost-effective production, making stamped heat sinks a viable option for various industries.

Thermal Conductivity

The thermal conductivity of a heat sink material significantly impacts its performance. Stamped heat sinks are often made from materials like aluminum, which possess excellent thermal conductivity properties. This allows for efficient heat transfer from the heat source to the fins, ensuring optimal cooling.

Compatibility with Different Power Levels

Stamped heat sinks can be designed to accommodate different power levels. By adjusting the fin density and thickness, as well as the overall size of the heat sink, it is possible to create a solution that can effectively dissipate heat generated by various power levels. This versatility makes stamped heat sinks suitable for a wide range of applications.

Ease of Installation

Installing a heat sink should be a straightforward process, and stamped heat sinks excel in this regard. Their design allows for easy installation and compatibility with standard mounting mechanisms, making them user-friendly and reducing assembly time.

Longevity and Reliability

Stamped heat sinks are known for their longevity and reliability. The stamping process ensures the creation of a robust and durable heat sink that can withstand harsh operating conditions. This durability translates into long-term performance and reliability, making stamped heat sinks a trusted choice for critical applications.

Application Areas

Stamped heat sinks find applications in various industries, including electronics, automotive, telecommunications, and aerospace. They are commonly used in power amplifiers, CPUs, LED lighting, motor drives, and other electronic devices where heat dissipation is crucial for optimal performance.