Introduction

heat sink ssr (Solid State Relay) is an electronic device that provides switching without any mechanical contacts. It can be used for various applications, such as lighting, heating, and motor control, or any other application where mechanical relays are used. In this article, we’ll discuss everything you need to know about heat sink SSRs.

What is a Heat Sink SSR?

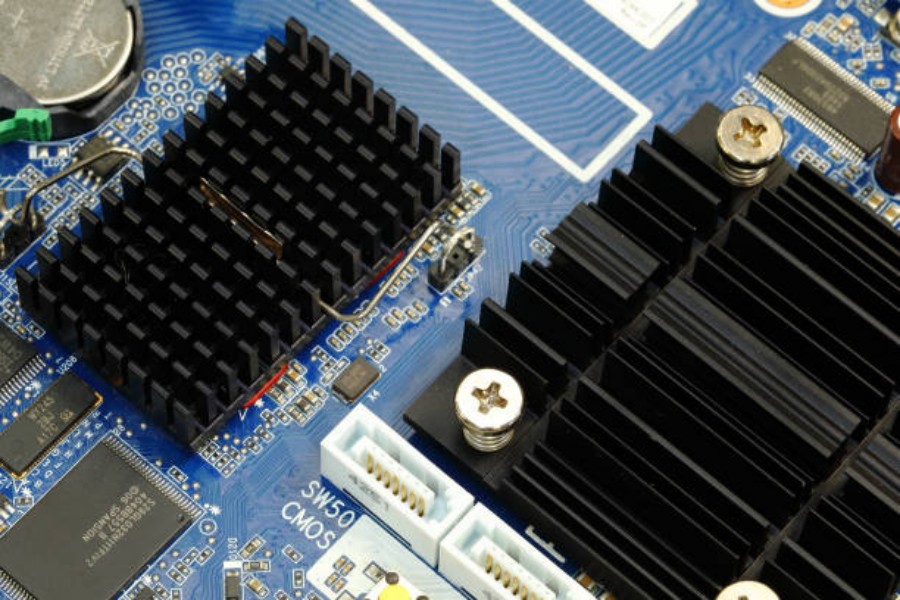

A Heat Sink SSR is a switch that uses a semiconductor device for switching instead of a mechanical relay. Heat sink SSRs provide noiseless switching and can switch high current loads without any noise or wear and tear of moving parts of the mechanical relay. They are used when fast switching speeds are necessary, and optimal performance is required.

How Does a Heat Sink SSR Work?

Heat sink SSRs use semiconductor devices, such as MOSFETs, IGBTs, or SCRs, for switching. These devices are connected to optocouplers, which isolate the high-voltage side of the circuit from the low-voltage side. The signal is transmitted via light, which eliminates any interference from external noise. The semiconductor device controls the flow of current to the load, and the heat sink helps to dissipate the generated heat.

Advantages of Using Heat Sink SSRs

Heat sink SSRs have several advantages over mechanical relays:

- Noiseless switching

- No moving parts, hence no wear and tear

- Fast switching speeds

- Optimal performance

- Longer lifespan

- Less maintenance required

Applications of Heat Sink SSRs

Heat sink SSRs can be used in various applications, such as:

- Lighting control

- Heating control

- Motor control

- Industrial automation

- Power supplies

- Robotics

Choosing the Right Heat Sink SSR

When choosing a heat sink SSR, the following factors should be considered:

- Maximum switching current

- Input voltage range

- Switching frequency

- Operating temperature range

- Load and ambient conditions

Installation of Heat Sink SSRs

Heat sink SSRs should be installed as follows:

- Ensure that the power supply is disconnected before installation

- Mount the heat sink SSR on a heat sink to dissipate generated heat

- Connect the power supply and the load to the appropriate terminals of the heat sink SSR

- Ensure that the wiring is correct, and there are no loose connections

- Switch on the power supply and test the heat sink SSR

Care and Maintenance of Heat Sink SSRs

Heat sink SSRs require minimal maintenance and care. However, the following precautions should be taken:

- Ensure that the heat sink is clean and free from dust and debris

- Check the wiring and connections periodically

- Replace any defective or damaged components immediately

Common Problems with Heat Sink SSRs

Some common problems with heat sink SSRs are:

- Overheating

- Short circuit

- Damage due to overvoltage

Conclusion

Heat Sink SSRs are an essential component for various applications, especially where fast switching speeds are necessary, and optimal performance is required. They have several advantages over mechanical relays and provide noiseless switching, long lifespan, and less maintenance. When choosing a heat sink SSR, several factors should be considered, including maximum switching current, input voltage range, load and ambient conditions, and operating temperature range.