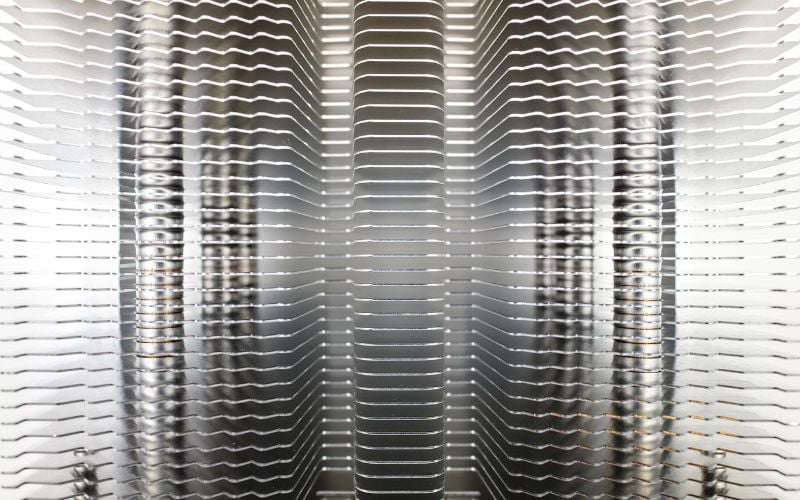

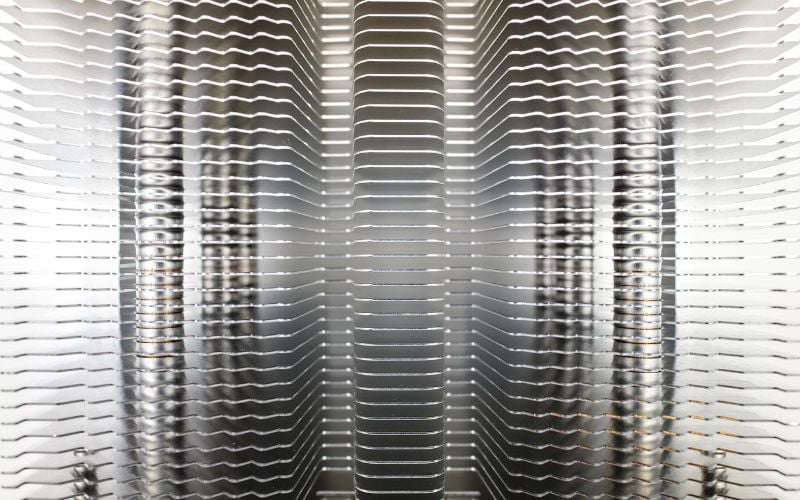

What is a Heatsink?

A heatsink is a passive component that helps dissipate heat away from electronic components. They are commonly used in computers, LEDs, and other electronic devices to prevent overheating.

The Importance of Heatsinks

Without heatsinks, electronic components can become damaged from excessive heat. Heatsinks help maintain the temperature of these components within safe operating limits, ensuring optimal performance and longevity.

Materials Used in Heatsinks

Heatsinks are typically made from materials with high thermal conductivity, such as aluminum or copper, to efficiently transfer heat. Aluminum heatsinks are more common due to their lightweight nature and cost-effectiveness.

Why Stamping?

Stamping is a popular manufacturing process for heatsinks due to its efficiency and cost-effectiveness. This method allows for high-volume production with consistent quality and precision.

The Stamping Process

The process of stamping a heatsink begins with a flat sheet of aluminum or copper. This sheet is then fed into a stamping press, where specialized molds and dies are used to shape and form the heatsink into its final design.

Benefits of Stamping

Stamping heatsinks allows for complex shapes and intricate designs to be created with ease. This method is well-suited for mass production, as it increases productivity and reduces lead times.

Surface Treatment

After stamping, heatsinks may undergo surface treatments such as anodizing or powder coating to improve their durability and corrosion resistance. These treatments also enhance the heatsink's appearance.

Quality Control

Throughout the stamping process, quality control measures are in place to ensure that each heatsink meets the required specifications. This includes inspecting dimensions, surface finish, and overall performance.

Applications of Stamped Heatsinks

Stamped heatsinks are used in a wide range of electronic applications, including computer processors, power supplies, and LED lighting. Their versatility and cooling efficiency make them an essential component in many devices.

Conclusion

In conclusion, the process of stamping a heatsink is a crucial step in producing efficient and reliable cooling solutions for electronic components. By understanding the intricacies of this process, manufacturers can meet the demands of modern technology with high-quality heatsinks.

Quote Inquiry

Contact us!