Exploring the advantages of copper heat sinks

Introduction

Copper heat sinks are widely used in various industries to dissipate heat generated by electronic components. In this article, we will explore the advantages of copper heat sinks and why they are preferred over other materials. From their excellent thermal conductivity to their durability, copper heat sinks offer numerous benefits that make them a popular choice in thermal management. Let's delve into the details and understand why copper heat sinks are a superior option for efficient heat dissipation.

Superior Thermal Conductivity

Copper is known for its exceptional thermal conductivity, which is one of the primary reasons why it is extensively used in heat sinks. Compared to other metals, such as aluminum or steel, copper has a much higher thermal conductivity. This means that copper heat sinks can efficiently transfer heat away from electronic components, preventing overheating and ensuring optimal performance. The high thermal conductivity of copper enables rapid heat dissipation, making it an ideal material for heat sinks.

Enhanced Heat Dissipation

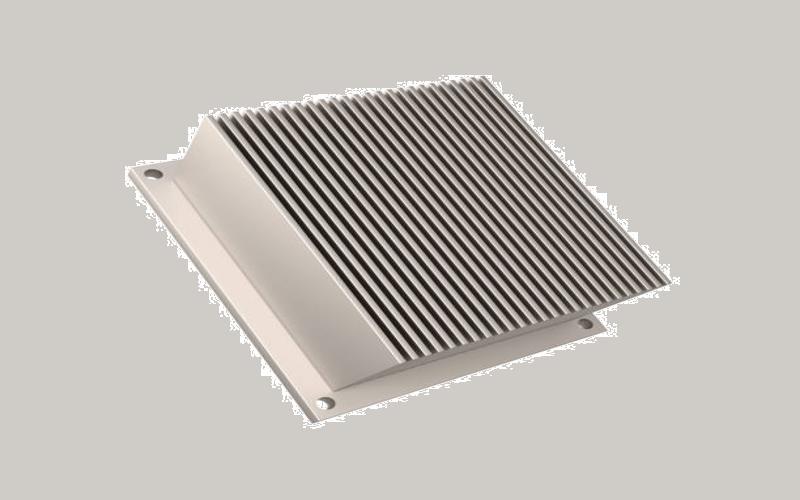

The design of copper heat sinks allows for enhanced heat dissipation. The fins and base of the heat sink are strategically designed to maximize the surface area, promoting better airflow and heat transfer. The larger surface area facilitates the dispersal of heat into the surrounding environment, preventing the buildup of heat and maintaining the temperature within acceptable limits. Copper heat sinks offer superior heat dissipation capabilities, making them highly effective in cooling electronic devices.

Durability and Reliability of copper heat sinks

Copper heat sinks are known for their durability and reliability. Copper is a robust metal that can withstand harsh operating conditions and extreme temperatures. Unlike other materials, copper does not degrade or corrode easily, ensuring the longevity of the heat sink. This durability makes copper heat sinks a long-lasting solution for thermal management, reducing the need for frequent replacements and minimizing maintenance costs.

Compatibility with Various Applications

Another advantage of copper heat sinks is their compatibility with a wide range of applications. Whether it's in the automotive industry, aerospace sector, or computer hardware, copper heat sinks can be customized to suit specific requirements. The versatility of copper allows for the creation of heat sinks in various shapes and sizes to fit different electronic devices. This flexibility makes copper heat sinks a popular choice across industries.

Efficient Energy Consumption

Copper heat sinks offer energy efficiency benefits as well. By effectively dissipating heat, they help prevent overheating of electronic components, which can lead to increased energy consumption. When electronic devices operate at lower temperatures, they require less power to maintain optimal performance. This energy-saving advantage not only reduces electricity costs but also contributes to a greener and more sustainable environment.

Cost-Effectiveness of copper heat sinks

While copper heat sinks may have a higher initial cost compared to other materials, they provide long-term cost-effectiveness. Their durability and reliability eliminate the need for frequent replacements, reducing maintenance and replacement expenses. Moreover, the superior thermal conductivity of copper ensures efficient heat dissipation, minimizing the risk of expensive damage to electronic components caused by overheating. In the long run, choosing copper heat sinks can result in significant cost savings.

Resistance to Corrosion

Copper possesses excellent resistance to corrosion, which is crucial in environments where heat sinks may be exposed to moisture or other corrosive elements. The corrosion resistance of copper ensures that the heat sink remains unaffected by external factors, maintaining its performance and efficiency over time. This resistance to corrosion is particularly valuable in industries such as marine, where heat sinks are exposed to saltwater or high humidity.

Ease of Manufacturing

Copper heat sinks are relatively easy to manufacture, thanks to copper's malleability and high thermal conductivity. The ease of manufacturing allows for cost-effective production of custom heat sinks tailored to specific requirements. Copper can be shaped and formed into intricate designs, optimizing the heat sink's performance and ensuring a perfect fit for the electronic device. This ease of manufacturing further adds to the overall advantages of copper heat sinks.

Conclusion

Copper heat sinks offer numerous advantages that make them the preferred choice for efficient heat dissipation. From their superior thermal conductivity and enhanced heat dissipation capabilities to their durability, compatibility, and resistance to corrosion, copper heat sinks excel in various aspects. Additionally, they provide energy efficiency benefits, cost-effectiveness, and ease of manufacturing. When it comes to thermal management, exploring the advantages of copper heat sinks reveals why they are widely used in industries where heat dissipation is critical for optimal performance and longevity of electronic devices.