Solid State Relays (SSRs) are used to switch electrical loads in various devices such as heaters, lamps, motors, and other industrial machinery. However, SSRs generate heat during operation, which can affect their performance and longevity. Heat sink for SSR is crucial in dissipating heat generated by the device. In this article, we will discuss everything you need to know about heat sink for SSR.

What is Heat Sink for SSR?

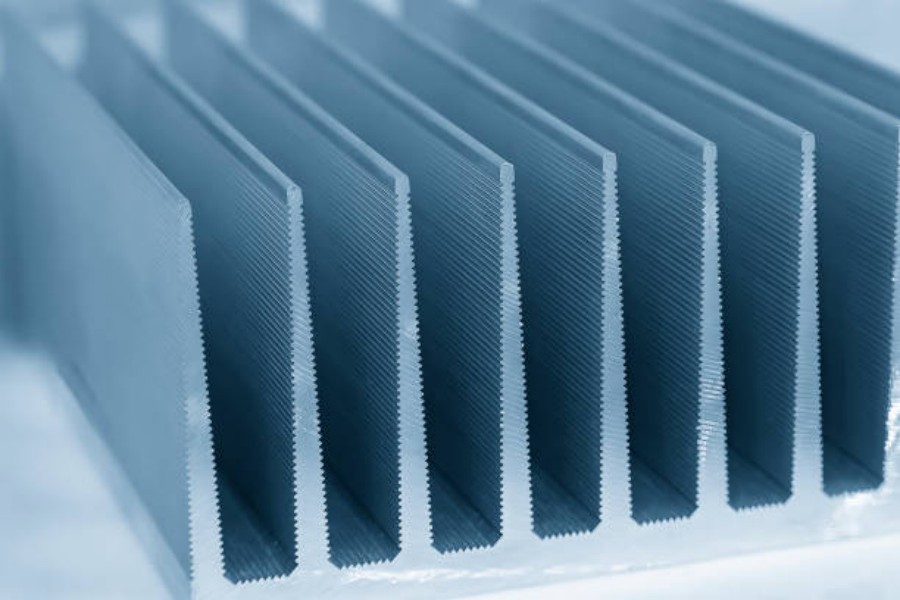

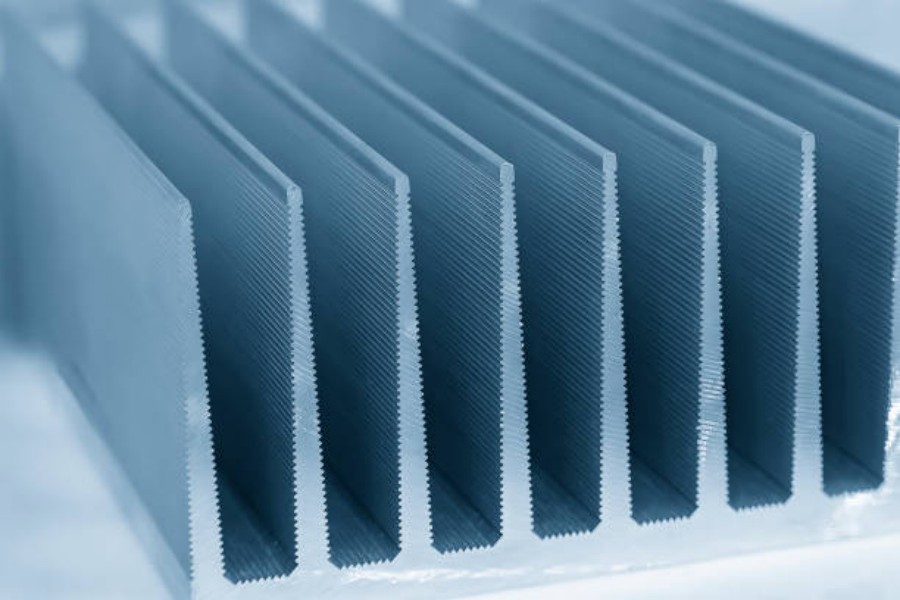

Heat sink for SSR is a mechanical component that helps to transfer heat away from the SSR to the surrounding environment. The heat sink is made up of a thermally conductive material, usually aluminum or copper, which absorbs the heat generated by the SSR and then dissipates it to the air or other coolant. Heat sinks are available in various sizes, shapes, and configurations, depending on the size and power rating of the SSR.

Types of Heat Sink for SSR

There are three types of heat sinks for SSR: passive heat sinks, active heat sinks, and liquid-cooled heat sinks. The passive heat sink is the most commonly used heat sink, which relies on natural convection to transfer heat to the surrounding air. The active heat sink uses a fan or blower to force air through the heat sink fins, which increases the heat transfer rate and cooling efficiency. The liquid-cooled heat sink utilizes a liquid coolant, such as water or oil, to absorb the heat from the SSR and then transfers it away from the heat sink.

Factors to Consider in Choosing a Heat Sink for SSR

Several factors must be considered when selecting a heat sink for SSR. These include the SSR thermal resistance or power dissipation, the environmental temperature, and the maximum operating temperature of the SSR and heat sink. Other factors include the physical size and mounting options of the heat sink, the thermal conductivity and surface area of the heat sink, and the series resistance and voltage drop of the SSR.

Advantages of Using Heat Sink for SSR

Using a heat sink for SSR provides several benefits. First, it increases the operational reliability and lifespan of the SSR by removing the excess heat generated during operation. Second, it reduces the risk of component failure due to overheating, which can cause damage to the equipment and property. Third, it improves the functionality and efficiency of the device by ensuring that the SSR operates within its temperature limits.

Installation and Maintenance of Heat Sink for SSR

Proper installation and maintenance of the heat sink for SSR are essential to ensure its optimal performance and longevity. The heat sink should be installed in a well-ventilated area that allows for adequate airflow and cooling. The heat sink should also be mounted securely and in direct contact with the SSR to maximize heat transfer. Regular maintenance, such as cleaning and inspection of the heat sink fins, is necessary to prevent blockages and maintain its thermal conductivity.

Compatibility with SSRs

Heat sink for SSRs are compatible with various types and sizes of SSRs, including those with AC or DC control inputs and single or multiple channels. Some heat sinks are designed specifically for SSRs with specific power ratings or series resistance. It is important to ensure that the heat sink is compatible with the SSR before purchasing or installing it.

Applications of Heat Sink for SSR

Heat sink for SSRs is used in various applications, including in the automotive industry, heating and cooling equipment, lighting systems, motor controls, and power distribution units. They are also used in medical devices, industrial automation, and renewable energy systems.

Cost of Heat Sink for SSR

The cost of heat sink for SSR depends on its type, size, and configuration. Passive heat sinks are generally less expensive than active or liquid-cooled heat sinks. However, the cost of the heat sink is insignificant compared to the overall cost of the device or equipment.

Conclusion

In conclusion, heat sink for SSR is essential in dissipating excess heat generated during the operation of the SSR. It improves the performance, reliability, and longevity of the device or equipment, reduces the risk of component failure, and ensures that the SSR operates within its temperature limits. The factors to consider in selecting a heat sink include the SSR thermal resistance, environmental temperature, physical size, and mounting options. Proper installation and maintenance are also necessary to ensure optimal performance and longevity.

Quote Inquiry