Introduction

Extrusion Heat Sink is an essential component in the manufacturing industry, especially in electronics. It is used to dissipate heat generated by electronic devices and make sure they function effectively. This article discusses all the essential aspects of extrusion heat sink, including its definition, materials used, manufacturing process, types, benefits, and applications.

What is an Extrusion Heat Sink?

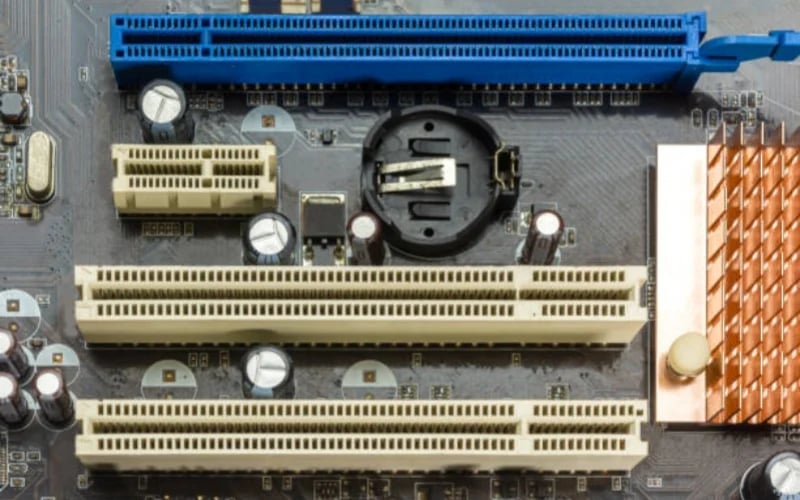

An extrusion heat sink is a machined aluminum or copper component designed to cool electronic devices and dissipate heat produced during normal operation. Extrusion heat sink operates by rapidly transferring heat from the electronic device to the surrounding environment through conduction.

Materials Used in Extrusion Heat Sinks

The material used in extrusion heat sink manufacturing is aluminum due to its light-weight and excellent thermal conductivity, but copper can also be used, but it is less common because of its high cost. Additionally, copper is denser than aluminum and can be challenging to extrude while maintaining the desired dimensions for the heat sink.

Manufacturing Process

The manufacturing process of extrusion heat sink relies on extrusion technology. The process begins with the cutting of aluminum bars into required lengths, which are then heated to a temperature that softens the aluminum and creates a heated part that is pushed through a die to create the extruded heat sink profile. Once the extrusion heat sink achieves the desired length, it is cut to the correct size or machined to meet exact specifications, and the surfaces are smoothed to enhance their heat transfer rate.

Types of Extrusion Heat Sinks

There are different types of extrusion heat sinks that cater to different needs and range from simple flat profile extrusion heatsinks, maximum performance geomar extrusion heat sinks, liquid cooled heat sinks, round heat sinks, and skived foil heat sinks.

Benefits of Extrusion Heat Sinks

The following are some of the benefits of using extrusion heat sinks:

- Lightweight and easy to install.

- They dissipate heat efficiently, keeping electronic devices running smoothly.

- They reduce the heat generated by electronic devices, thus extending their life span.

- They are affordable and offer an excellent return on investment to electronics manufacturers.

- They are corrosion-resistant and can withstand harsh environmental conditions.

Applications of Extrusion Heat Sink

Extrusion heat sinks have extensive applications in different industries, including:

- Information Technology (IT) and Telecommunication industries.

- Automotive Industry

- LED lighting industry

- Solar panel industry

- Power electronic devices

- Medical device industry

- Refrigeration and air conditioning industry to name a few.

Conclusion

An extrusion heat sink is a crucial component for many industries that use electronic devices. It ensures that electronic devices run efficiently and effectively by dissipating heat produced during operation. This article has discussed all the essential aspects of extrusion heat sink, including its definition, materials used, manufacturing process, types, benefits, and applications.