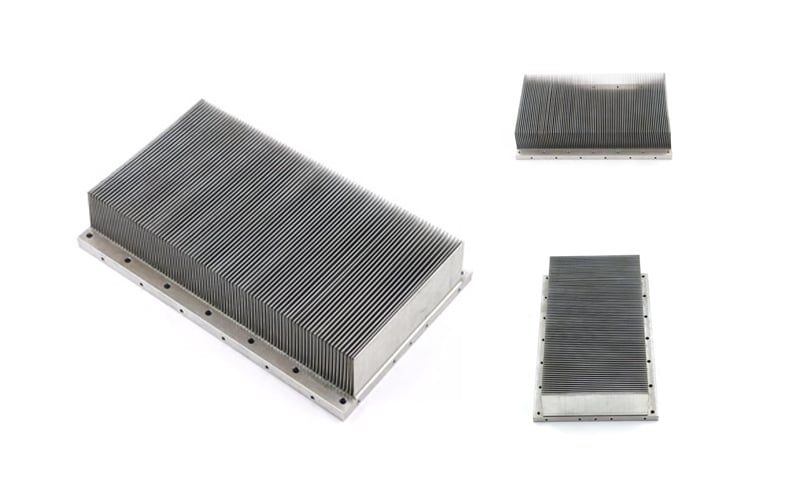

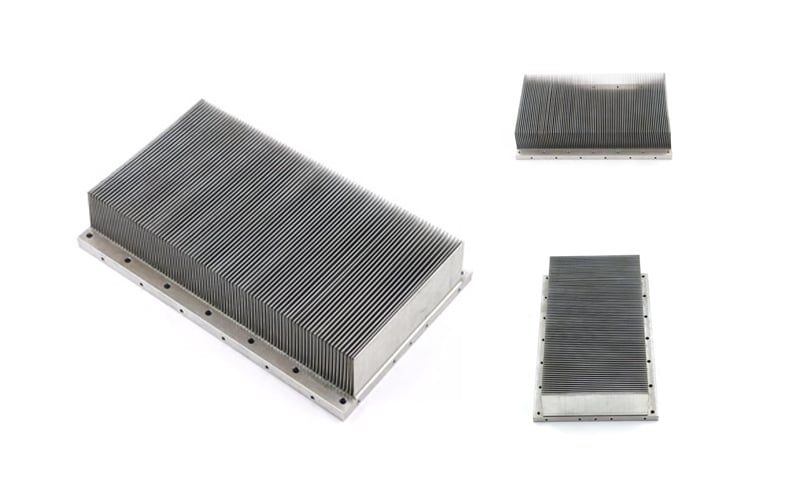

Copper vs Aluminum: The Battle of Heat Sink Materials

When it comes to selecting the right material for skived heat sinks, copper and aluminum are two popular choices. Both materials have their unique properties and benefits, making it essential to understand the differences between them to make an informed decision for your application.

Thermal Conductivity: Copper Takes the Lead

One of the primary factors to consider when choosing a heat sink material is thermal conductivity. Copper has a significantly higher thermal conductivity than aluminum, making it more efficient at dissipating heat. This means that copper skived heat sinks can effectively cool electronic components faster than their aluminum counterparts.

Weight and Cost: Aluminum's Lightweight Advantage

While copper may have better thermal conductivity, aluminum has the upper hand when it comes to weight and cost. Aluminum is much lighter than copper, making it ideal for applications where weight is a concern. Additionally, aluminum is more cost-effective than copper, making it a more budget-friendly option for large-scale projects.

Corrosion Resistance: Copper Trumps Aluminum

Corrosion resistance is another critical factor to consider, especially in environments with high humidity or exposure to corrosive elements. Copper is naturally more resistant to corrosion compared to aluminum, making it a more durable option for long-term use.

Machinability and Formability: Aluminum Wins Out

Aluminum is known for its excellent machinability and formability, making it easier to work with during the manufacturing process. Unlike copper, which can be challenging to machine, aluminum skived heat sinks can be easily customized to meet specific design requirements.

Thermal Expansion: Copper Offers Stability

Thermal expansion is a crucial consideration in heat sink applications, as materials expand and contract with temperature changes. Copper has a lower coefficient of thermal expansion compared to aluminum, providing better stability and reliability over a wide temperature range.

Electrical Conductivity: Copper's Conductive Advantage

In applications where electrical conductivity is a factor, copper is the preferred choice. Copper has superior electrical conductivity compared to aluminum, making it ideal for heat sinks used in electronic components where electrical signal integrity is crucial.

Surface Finish and Aesthetics: Aluminum Shines Bright

If aesthetics are important for your application, aluminum heat sinks offer a sleek and modern appearance. Aluminum can be anodized in various colors and finishes, providing both functionality and visual appeal. Copper, on the other hand, has a classic look but may require more maintenance to prevent tarnishing.

Environmental Impact: Aluminum's Eco-Friendly Profile

For environmentally conscious applications, aluminum is the more sustainable choice. Aluminum is highly recyclable and has a lower environmental impact compared to copper, making it a greener option for heat sink manufacturing.

Conclusion: Choosing the Right Material for Your Application

In conclusion, the choice between copper and aluminum skived heat sinks ultimately depends on your specific requirements and priorities. While copper offers superior thermal conductivity and corrosion resistance, aluminum excels in terms of weight, cost, and machinability. Consider the unique properties of each material and weigh them against your project's needs to make the best decision for your application.

Quote Inquiry

contact us