What Is a copper tube liquid cold plate?

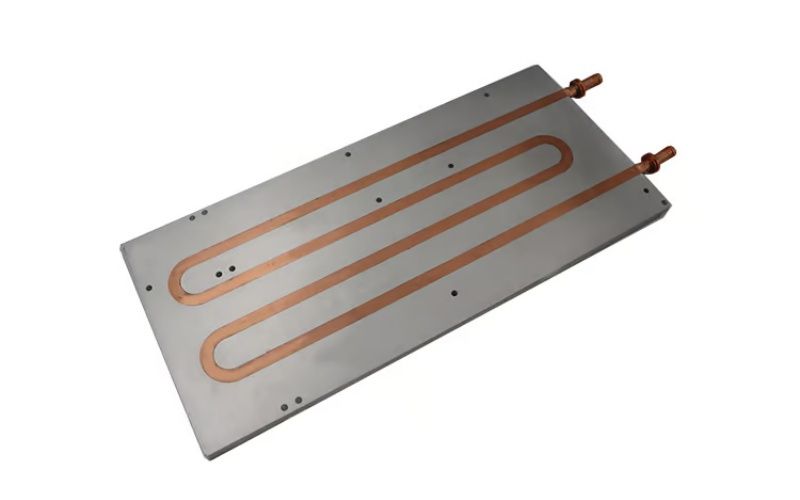

A copper tube liquid cold plate is a cooling solution used in electronic devices to prevent them from overheating. It is a passive cooling system that transfers heat from electronic components to a liquid coolant circulating through copper tubes embedded in a flat plate. The cooled liquid then carries away the heat generated, dissipating it into the air or through a liquid-to-air heat exchanger.

How Does a Copper Tube Liquid Cold Plate Work?

The copper tube liquid cold plate works on the principle of heat transfer. When electronic components generate heat, it is absorbed by the copper tubes. As the coolant circulates through the tubes, it picks up the heat and carries it away from the components. The liquid coolant then releases the heat through natural convection or a heat exchanger. The large surface area of the cold plate enables efficient heat dissipation, making it an effective cooling solution for high-performance electronic devices.

What Are the Benefits of Using a Copper Tube Liquid Cold Plate?

The use of a copper tube liquid cold plate offers several benefits, including:

- Efficient heat dissipation

- Improved device reliability

- Reduced power consumption

- No moving parts

- Quiet operation

Where Are Copper Tube Liquid Cold Plates Used?

Copper tube liquid cold plates are used in a range of electronic devices that generate a high amount of heat, such as:

- Power electronics

- Laser diodes

- High-performance CPUs and GPUs

- LED lighting

- Solar inverters

- Telecommunications equipment

- Industrial automation systems

- Electric vehicles

What Are the Different Types of Copper Tube Liquid Cold Plates?

There are several types of copper tube liquid cold plates, including:

- Formed Tube Cold Plates - Made by brazing copper tubes onto a flat plate

- Extruded Tube Cold Plates - Made by extruding a flat plate with embedded copper tubes

- Finned Tube Cold Plates - Made by attaching fins to the copper tubes to increase surface area for improved heat dissipation

How to Select a Copper Tube Liquid Cold Plate?

When selecting a copper tube liquid cold plate, several factors need to be considered, including:

- Thermal performance requirements

- Coolant type and flow rate

- Plate size and shape

- Tubing material and diameter

- Mounting options

- Cost and lead time

What Are the Advantages of Copper in Liquid Cold Plates?

Copper is an excellent material for liquid cold plates due to its high thermal conductivity, corrosion resistance, and cost-effectiveness. Copper easily transfers heat from the electronic components to the coolant, reducing the device's temperature. Copper is also durable, long-lasting, and compatible with several types of coolants, making it an ideal material for liquid cold plates.

How to Maintain Copper Tube Liquid Cold Plates?

Maintaining copper tube liquid cold plates is essential for ensuring optimal performance and longevity. Proper maintenance includes regular cleaning, inspection, and replacement of damaged tubes or fins. It is also essential to monitor the coolant flow rate and temperature regularly and replace it when necessary to prevent contamination, corrosion, or fouling.

What are the Alternatives to Copper Tube Liquid Cold Plates?

Some alternatives to copper tube liquid cold plates include air cooling, heat sinks, and liquid-to-air heat exchangers. However, copper tube liquid cold plates offer superior thermal performance, reliability, and noise reduction, making them the preferred choice for high-performance electronic devices.

Conclusion

Copper tube liquid cold plates are an effective cooling solution for high-performance electronic devices that generate a high amount of heat. They offer several benefits over other cooling solutions, including efficient heat dissipation, improved reliability, reduced power consumption, and quiet operation. When selecting a copper tube liquid cold plate, several factors need to be considered, such as thermal performance requirements, coolant type, plate size and shape, tubing material and diameter, mounting options, cost, and lead time.