Introduction to Cold Plate Configurations

Cold plate configurations are critical components in various cooling systems. They are designed to efficiently dissipate heat generated by electronic devices. Two common types of cold plate configurations are the serpentine and parallel flow designs. In this article, we will compare these two configurations in terms of their advantages, disadvantages, and applications.

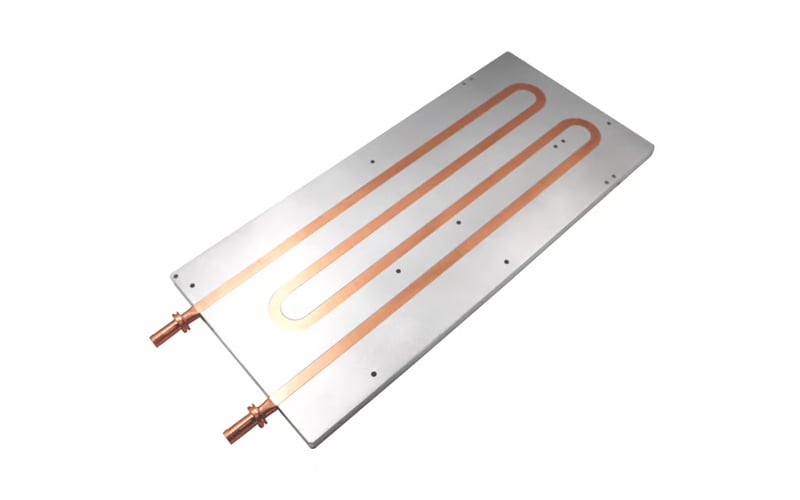

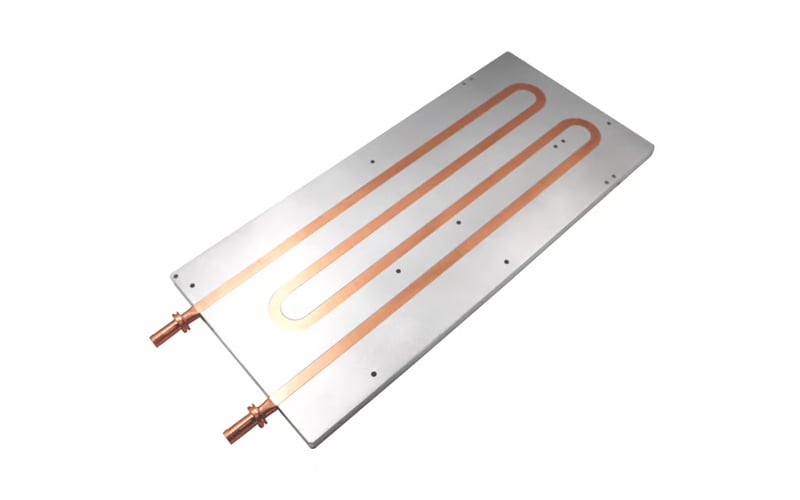

Understanding Serpentine Flow Design

The serpentine flow design involves a single fluid inlet that flows through a series of channels in a zig-zag pattern before exiting the plate. This design is known for its compact size and efficient heat transfer capabilities. Serpentine flow cold plates are commonly used in small-scale applications where space is limited.

Exploring Parallel Flow Design

On the other hand, the parallel flow design consists of multiple fluid inlets and outlets that run parallel to each other. This design allows for better control over the flow distribution and can accommodate higher flow rates compared to serpentine flow cold plates. Parallel flow cold plates are often utilized in high-power electronic systems.

Heat Transfer Efficiency

When it comes to heat transfer efficiency, serpentine flow cold plates are generally more efficient than parallel flow cold plates. The serpentine design creates a longer flow path for the coolant, resulting in improved heat dissipation. However, parallel flow cold plates offer better flow uniformity and can handle higher thermal loads.

Pressure Drop Considerations

In terms of pressure drop, serpentine flow cold plates typically have lower pressure drop compared to parallel flow cold plates. This is due to the longer flow path and reduced flow velocity in the serpentine design. Lower pressure drop can be advantageous in systems where pumping power is a concern.

Manufacturability and Cost

When it comes to manufacturability and cost, serpentine flow cold plates are often easier and cheaper to manufacture than parallel flow cold plates. The simple design of the serpentine configuration requires fewer components and can be mass-produced more efficiently.

Application Specific Considerations

The choice between serpentine and parallel flow cold plate configurations ultimately depends on the specific requirements of the cooling system. Serpentine flow cold plates are ideal for compact systems with limited space, while parallel flow cold plates are better suited for high-power applications with demanding thermal loads.

Environmental Impact

In terms of environmental impact, both serpentine and parallel flow cold plates can contribute to overall energy efficiency in electronic systems. By effectively dissipating heat, these cold plates can help reduce the energy consumption of cooling systems and improve the overall sustainability of electronic devices.

Conclusion

In conclusion, the choice between serpentine and parallel flow cold plate configurations should be based on the specific needs and constraints of the cooling system. While serpentine flow cold plates are more compact and efficient in heat transfer, parallel flow cold plates offer better flow control and handling of high thermal loads. Both designs have their advantages and are widely used in various electronic applications.

Quote Inquiry

Contact us