The Battle of the Heatsinks: Aluminum vs Copper

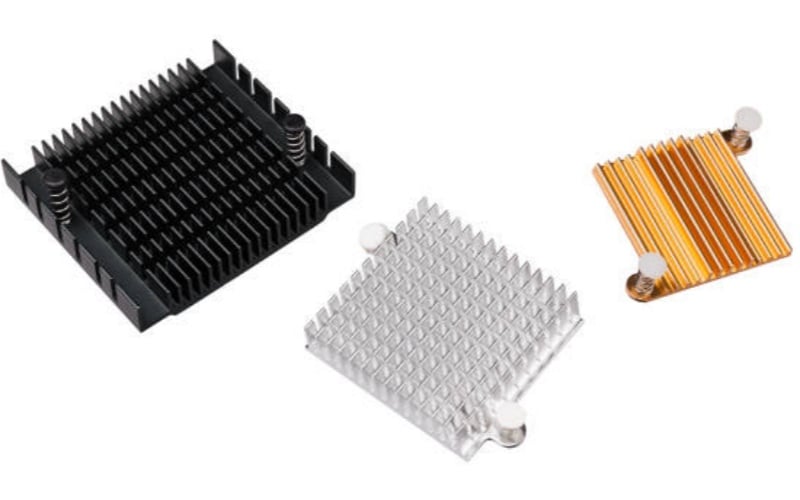

When it comes to cooling electronic devices, heatsinks play a crucial role in dissipating heat. Two popular materials used for heatsinks are aluminum and copper. Both have their own unique properties and advantages, but which one is better? In this article, we will explore the differences between aluminum heatsinks and copper heatsinks to help you make an informed decision for your cooling needs.

1. Thermal Conductivity: The Key Factor

One of the most important factors to consider when choosing a heatsink material is thermal conductivity. Thermal conductivity measures a material's ability to transfer heat. In this regard, copper takes the lead. Copper has a thermal conductivity of around 400 W/mK, which is significantly higher than aluminum's thermal conductivity of approximately 200 W/mK. This means that copper heatsinks can transfer heat more efficiently than aluminum heatsinks.

2. Weight: Lightweight Aluminum

When it comes to weight, aluminum heatsinks have a clear advantage. Aluminum is a lightweight material, making it an ideal choice for applications where weight is a concern. This is especially important in industries such as aerospace, where reducing weight is crucial for fuel efficiency. Copper, on the other hand, is significantly heavier than aluminum, which may limit its use in certain applications.

3. Cost: Affordable Aluminum

Cost is another important consideration when choosing between aluminum and copper heatsinks. Aluminum is generally less expensive than copper, making it a more budget-friendly option. This affordability makes aluminum heatsinks a popular choice, especially for mass-produced electronic devices. Copper heatsinks, on the other hand, tend to be more expensive due to the higher cost of the material itself.

4. Corrosion Resistance: Aluminum's Achilles Heel

One area where copper outshines aluminum is corrosion resistance. Copper is highly resistant to corrosion, making it suitable for environments where moisture or other corrosive elements are present. On the other hand, aluminum is more prone to corrosion and requires additional coatings or treatments to protect it from deterioration. If your device will be exposed to harsh conditions, copper heatsinks may be a better choice.

5. Electrical Conductivity: Copper Takes the Lead

When it comes to electrical conductivity, copper is the clear winner. Copper is an excellent conductor of electricity, which is why it is widely used in electrical wiring and other applications that require high conductivity. Aluminum, although it is also a good conductor, falls short compared to copper. If your device requires both efficient heat dissipation and electrical conductivity, copper heatsinks are the way to go.

6. Machinability: Aluminum's Advantage

Aluminum is known for its excellent machinability, which makes it easier to work with and customize. It can be easily shaped, cut, and drilled, allowing for intricate designs and precise manufacturing. Copper, on the other hand, is more difficult to machine due to its higher hardness and malleability. If you require complex heatsink designs or customization options, aluminum heatsinks provide greater flexibility.

7. Thermal Expansion: Consider Compatibility

Thermal expansion refers to how a material expands or contracts with temperature changes. Copper and aluminum have different rates of thermal expansion, which can be a crucial factor in certain applications. If your device requires close contact between the heatsink and the heat source, it is important to consider the compatibility of the materials to avoid potential issues caused by thermal expansion mismatch.

8. Aesthetics: Sleek Aluminum

If visual appeal is important to you, aluminum heatsinks are often favored for their sleek and modern look. Aluminum can be anodized or painted in various colors to match the design aesthetics of your device. Copper, on the other hand, has a distinct reddish-brown color that may not suit every application. The choice between the two materials depends on the desired visual impact and overall design goals.

9. Environmental Impact: Aluminum's Sustainability

When considering the environmental impact, aluminum has an advantage over copper. Aluminum is a highly recyclable material, with a recycling rate of over 90%. It can be recycled numerous times without losing its properties, making it a more sustainable choice. Copper, although also recyclable, has a lower recycling rate and requires significant energy for the recycling process.

10. Application Specific Considerations

Ultimately, the choice between aluminum and copper heatsinks depends on the specific requirements of your application. Consider factors such as thermal conductivity, weight, cost, corrosion resistance, electrical conductivity, machinability, thermal expansion, aesthetics, and environmental impact. Analyze your device's cooling needs and prioritize the factors that are most important for its optimal performance.

In conclusion, both aluminum and copper heatsinks have their own advantages and disadvantages. Copper heatsinks offer superior thermal conductivity and electrical conductivity but come at a higher cost. Aluminum heatsinks, on the other hand, are lightweight, more affordable, and easier to machine. Consider the specific demands of your application to make an informed decision between these two popular heatsink materials.