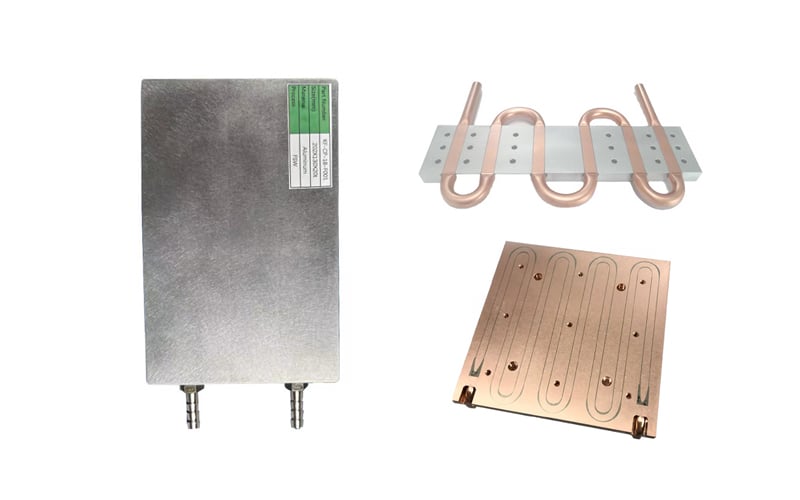

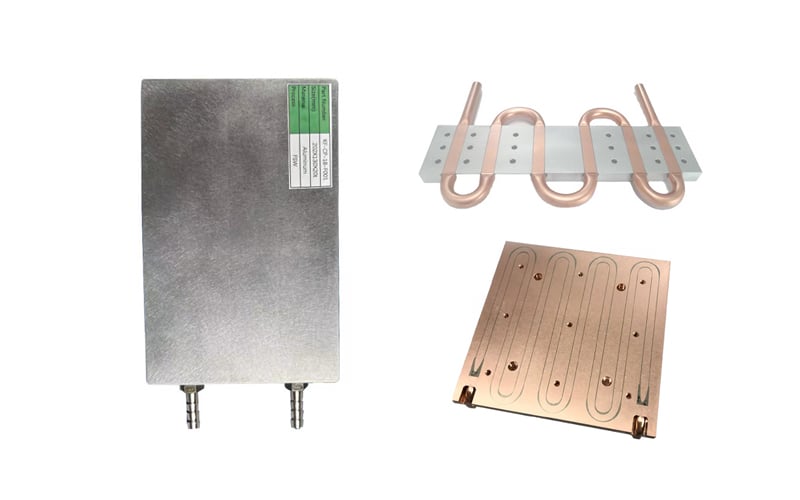

The Evolution of Custom Cold Plate Production

Additive manufacturing has revolutionized the way custom cold plates are produced. Traditional methods often involve time-consuming processes and high costs, but with additive manufacturing, manufacturers can create intricate designs with greater efficiency.

Cost-Effective Solutions for Custom Cold Plates

One of the biggest advantages of additive manufacturing in custom cold plate production is cost-effectiveness. Manufacturers can save on material costs and reduce waste by only using the necessary materials, making it a more sustainable option in the long run.

Customization and Design Flexibility

Additive manufacturing allows for unparalleled customization and design flexibility in custom cold plate production. Manufacturers can easily modify designs to meet specific requirements, leading to more efficient cooling solutions for various applications.

Improved Performance and Efficiency

By utilizing additive manufacturing in custom cold plate production, manufacturers can improve the performance and efficiency of cooling systems. Custom designs can optimize thermal conductivity and heat dissipation, leading to better overall performance.

Reduced Lead Times for Custom Cold Plates

Traditional manufacturing methods often come with long lead times, but additive manufacturing has significantly reduced production time for custom cold plates. Manufacturers can quickly prototype and produce custom designs, speeding up the manufacturing process.

Enhanced Quality Control and Testing

Additive manufacturing allows for enhanced quality control and testing in custom cold plate production. Manufacturers can easily inspect and test prototypes, ensuring that the final product meets all quality standards and performance requirements.

Sustainability and Environmental Benefits

In addition to cost-effectiveness, additive manufacturing in custom cold plate production also offers sustainability and environmental benefits. By minimizing waste and using only necessary materials, manufacturers can reduce their environmental impact.

Application in Various Industries

The versatility of additive manufacturing makes it suitable for custom cold plate production in various industries. From electronics to automotive, manufacturers can create tailored cooling solutions that meet the unique needs of each industry.

Future Prospects and Innovations

As additive manufacturing technology continues to advance, the future prospects for custom cold plate production look promising. Manufacturers can expect further innovations in design complexity, material efficiency, and overall performance.

Conclusion: A Game Changer in Custom Cold Plate Production

In conclusion, additive manufacturing has become a game changer in custom cold plate production. With its cost-effectiveness, customization abilities, and efficiency improvements, manufacturers can expect a revolution in the way custom cold plates are designed and produced.

Quote Inquiry

Contact us